2205 (UNS S32205) duplex stainless steel has a wide range of applications due to its excellent combination of corrosion resistance, mechanical properties and cost-effectiveness. Some common applications for 2205 duplex stainless steel include:

Offshore and marine environments:

– Offshore oil and gas platforms

– Subsea equipment and pipelines

– Desalination plants and seawater intake systems

– Coastal and port infrastructure (e.g. piers, docks, breakwaters)

Chemical and Petrochemical Processing:

– Containers, tanks and pipes for chemical plants

– Equipment for handling corrosive chemicals and corrosive liquids

– Refineries and petrochemical facilities

Pulp and Paper Industry:

– Digesters, evaporators and other process equipment

– Pipes and valves for pulp and paper mills

Water and wastewater treatment:

– Desalination plant components

– Wastewater treatment equipment

– Drinking water distribution system

Generation:

– Nuclear power plant components

– Coal-fired power plant flue gas desulfurization system

– Geothermal power plant equipment

Building and Structural Applications:

– Building facades and cladding systems

– Bridges, interchanges and other infrastructure

– Urban furniture and design elements

Low and high temperature applications:

– Liquefied Natural Gas (LNG) Facilities

– Petrochemical plants and power generation equipment

– Excellent resistance to pitting, crevice and stress corrosion cracking

– High strength-to-weight ratio, providing design flexibility and weight savings

– Maintains mechanical properties and corrosion resistance at both high and low temperatures

– Good solderability and correct workmanship

– Cost effective compared to super duplex stainless steel

-

2023-2-15 Laser hybrid welding related technical features

2023-2-15 Laser hybrid welding related technical features -

2024-9-27 400 / 2.4360 stainless steel structural profiles advantages and applications

2024-9-27 400 / 2.4360 stainless steel structural profiles advantages and applications -

2024-9-16 2205 stainless steel Hollow Sections and H Sections applications

2024-9-16 2205 stainless steel Hollow Sections and H Sections applications -

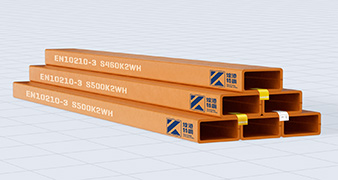

2024-7-15 Technical delivery conditions for high strength and weather resistant steels

2024-7-15 Technical delivery conditions for high strength and weather resistant steels -

2024-9-25 UNS N08926 Super Stainless Steel Structural Profiles

2024-9-25 UNS N08926 Super Stainless Steel Structural Profiles -

2024-9-21 High strength S690 steel VS 960 steel

2024-9-21 High strength S690 steel VS 960 steel -

2024-9-25 Introduction to 254SMO and UNS S31254 Super Stainless Steel

2024-9-25 Introduction to 254SMO and UNS S31254 Super Stainless Steel