To start this process smoothly:

- Send us a drawing: It can be hand-drawn or in CAD format, whichever you prefer.

- Provide us with information about your project: material grade, quantity, length, surface finish, specific testing requirements, required dimensional tolerances, and any other relevant details.

- Unit B, 9/F, Worldwide Centre, 123 Tung Chau Street, Tai Kok Tsui Kowloon.HongKong

- T: +852-92992995

- E: sales@peakkong.com

- Standard: DIN 1024, EN10025-5

- Technology: ISO 15614-11 or ISO 15614-14

- Fabrication Craftsmanship: ASTM A1069, EN13919

- Steel grade: S235J2W, S355J2WP, S355J0W, S355J0WP, S355K2W(A588Gr.A, A588Gr.B, A588Gr.C)

- Tolerance: EN 10163-3

- Certificate: According to EN 10204 - Type 2.2 or 3.1b

- Corten Steel Structural Sections is a weathering steel grade according to EN 10025-5 / ASTM A588 for sustainable, decorative, and cost-efficient structures with uncoated steel sections。

- Self-protecting, durable and attractive, weathering steel is ideal for a whole range of outdoor structures in exposed locations including bridges, buildings and catenary gantries on railway lines

- educed construction cost along with construction time

- reduced cost of maintenance as well as time of maintenance operation

- no environmental impact due to absence of maintenance operations and residue

-

Weather resistance

Because Corten steel is highly weather-resistant, it can be used without painting. Paintless applications not only have the economic advantage of reducing repainting costs, but also provide aesthetic benefits associated with a calm color that protects the rust layer. The weather resistance depends on the product grade and the use environment. The weather resistance of Corten steel is 4-8 times that of ordinary steel.

-

Solderability

Trace amounts of alloying elements such as copper (Cu) and chromate (Cr) are added to Corten steel to ensure high weather resistance while reducing the carbon content to provide proper weldability. Corten steel can be welded by manual welding, gas shielded welding or submerged arc welding. In addition, spot welding can also be used for thin thicknesses of weathering steel.

-

Processability

Corten steel has similar processing properties (cold forming, hot forming and gas cutting) as ordinary steel of the same strength. For strip rolled products, it is best to bend the axis transversely to the main rolling direction. For applications requiring higher formability, steels complying with EN10155 can provide guaranteed changeability.

- The steel grades with the best weather resistance are S355JOWP, S355J2JOWP and Corten A. However, due to the use of cinnamon as an alloying element, the impact strength of these steel grades is lower than that of other weathering steels. These weathering steels are best suited for steel plate structures where there is no risk of brittle fracture.

- When the risk of brittle fracture must be considered in the design due to high material thickness, low operating temperatures or other reasons, it is better to choose other EN 10155 steels or Corten B. In this way, the impact strength requirements of hot-rolled steel can be consistent with the impact strength requirements of general steel structures.

- At temperatures above 540°C, S355J0WP, S355J2WP, Corten A and Corten B have significantly higher spalling resistance than general structural steel.

- As a structural profile manufacturer, our steel products have received the CE marking and have been tested to the highest standards, providing quality and assurance to the construction market.

- We are ISO 9001:2015 certified, and all materials are tested in our independently accredited ISO 17025 testing laboratory to the highest standards, ensuring full traceability.

- Our Weathering Steel Sections are manufactured according to EN 10025-5. Following this specification, strict impact tests are conducted at specified temperatures to ensure full compliance with construction product regulations.

- We are also certified under the environmental and sustainability standard BES 6001, which ensures our commitment to responsible sourcing of materials.

- Our experienced team of laser welding experts provides specialized technical support to our customers, including detailed high-strength low-alloy profile solutions for addressing specific processing challenges and developing new and more advanced steel grades for increasingly demanding applications.

PeakKong Special Steel applies Peakkong delivery conditions during the delivery process, and adds that both parties will comply with applicable legal and regulatory requirements and will not engage in any unethical business practices.

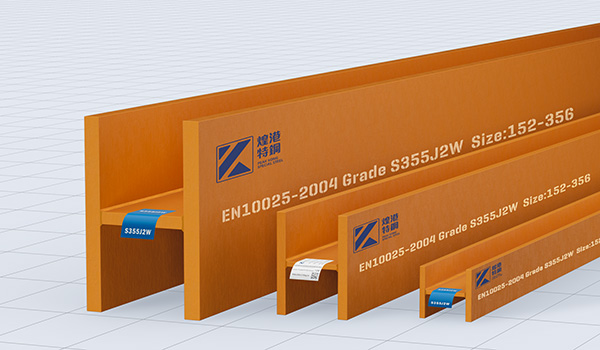

The products produced by PeakKong Special Steel.Weathering Structural steel sections(Laser Fusion) The technical delivery conditions of our products meet the respective requirements. Dimensions and tolerances are defined according to the relevant steel material standards. Engineering work complies with the respective standards.

Weathering Structural steel sections(Laser Fusion) Equipped with strapping tags and Peakkong Special Steel product tags to achieve comprehensive traceability and identification. According to the corresponding steel standards, corresponding material certificates will be provided.

Unit B, 9/F, Worldwide Centre, 123 Tung Chau Street, Tai Kok Tsui Kowloon.HongKong.

T: +852-29811161

E: sales@peakkong.com

No. 1 Building 1, No. 6 Xiegang Jinhai Road, Xiegang Town, Dongguan City, Guangdong Province.

T: 0769-82869307

E: admin@peakkong.com

+

+