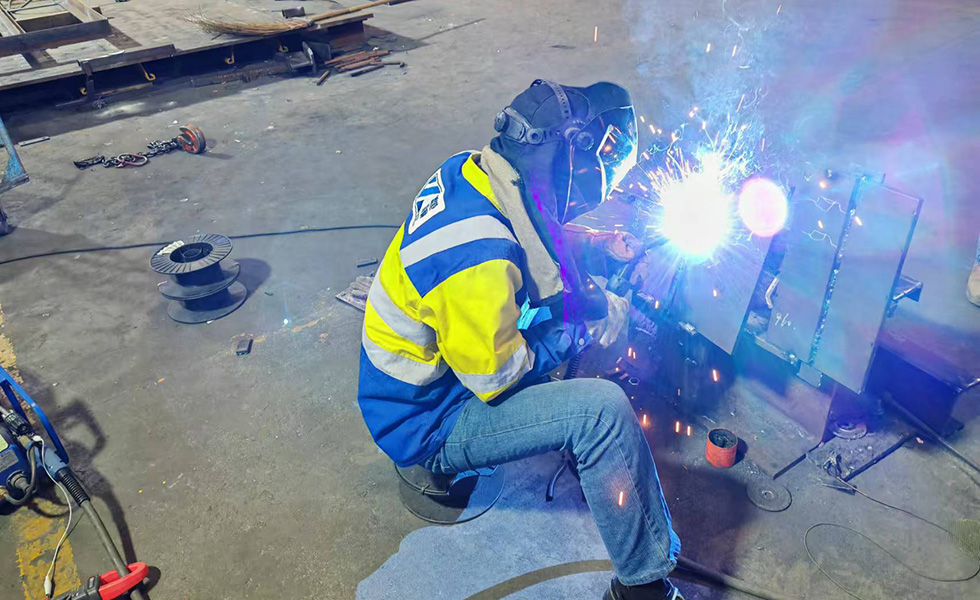

In December 2024, the welding team at Peak Kong Special Steel achieved another milestone by successfully completing the procedure qualification for PF (vertical-up welding) and PC (horizontal fixed welding) on S960QL ultra-high-strength steel. The team also passed the rigorous certification process of the Hong Kong Laboratory Accreditation Scheme (HOKLAS), earning the welding procedure qualification certificate.

This achievement further solidifies Peak Kong Special Steel’s leadership in high-strength steel welding technology and sets a new quality benchmark for the widespread application of premium steel materials in global markets.

S960QL is an ultra-high-strength steel known for its exceptional mechanical properties and extremely high tensile strength, making it widely used in bridges, buildings, marine engineering, and large machinery. However, the welding process for S960QL presents significant challenges, particularly in PF (vertical-up welding) and PC (horizontal fixed welding) positions, which demand precise control of welding parameters and advanced operational techniques.

After multiple rounds of testing and optimization, the welding team at Peak Kong Special Steel successfully achieved high-quality weld formation, controlled the risk of cracks in the heat-affected zone, and minimized welding deformation. The weld quality passed in this assessment not only meets international standards but also satisfies the rigorous certification requirements of HOKLAS, showcasing Peak Kong Special Steel’s technical strength in the high-end welding field.

The Hong Kong Laboratory Accreditation Scheme (HOKLAS) is an internationally recognized laboratory certification system with strict and impartial standards. Peak Kong Special Steel successfully passed the HOKLAS audit during this assessment, obtaining the welding procedure certification. This achievement marks the company’s welding technology as reaching world-class standards. The certification not only provides strong support for the company’s expansion into international markets but also further enhances its brand influence within the industry.

The welding procedures accredited by HOKLAS will be widely applied in the manufacturing of complex structures made from ultra-high-strength steels, including large bridges, high-rise buildings, marine engineering equipment, and energy infrastructure. Peak Kong Special Steel is committed to providing stronger, lighter, and more efficient steel solutions for customers through technological innovation and quality improvement.

In the future, Peak Kong Special Steel will continue to focus on technological breakthroughs as its core driving force, further deepening its expertise in the field of high-strength steel. The company aims to provide global customers with advanced steel manufacturing technologies and customized services, driving the steel industry towards higher levels of development.

-

2024-12-06 Peak Kong Special Steel participated in the 2024 Singapore Asia Stainless Steel Exhibition.

2024-12-06 Peak Kong Special Steel participated in the 2024 Singapore Asia Stainless Steel Exhibition. -

2024-1-02 Celebrating the application of laser welded stainless steel structural profiles in Yuen Long Sewage Treatment Plant

2024-1-02 Celebrating the application of laser welded stainless steel structural profiles in Yuen Long Sewage Treatment Plant -

2024-12-06 A warm welcome to the Civil Division of the Hong Kong Institution of Engineers for visiting the Peak Kong Special Steel factory.

2024-12-06 A warm welcome to the Civil Division of the Hong Kong Institution of Engineers for visiting the Peak Kong Special Steel factory. -

2024-8-01 Welcome to the High-Strength Steel Processing Delegation Visiting Our Company

2024-8-01 Welcome to the High-Strength Steel Processing Delegation Visiting Our Company -

2025-1-11 Peak Kong Special Steel Wins APAC-2024 Laser Welding Structural Profile Manufacturer of the Year Award

2025-1-11 Peak Kong Special Steel Wins APAC-2024 Laser Welding Structural Profile Manufacturer of the Year Award -

2025-1-06 The welding team at Peak Kong Special Steel has successfully completed the welding procedure qualification for duplex stainless steel and super duplex stainless steel 2205/2507.

2025-1-06 The welding team at Peak Kong Special Steel has successfully completed the welding procedure qualification for duplex stainless steel and super duplex stainless steel 2205/2507. -

2024-12-06 Peak Kong Special Steel Showcases Advanced High-Strength Steel Structural Profiles at WCFS International Conference

2024-12-06 Peak Kong Special Steel Showcases Advanced High-Strength Steel Structural Profiles at WCFS International Conference