Advanced high-strength steel structural profiles refer to structural profiles whose tensile strength reaches or exceeds ≥ 550 MPa. (H-beam, I-beam, channel steel, angle iron, unequal angle iron, square tube, flat tube, steel pipe, etc.). Commonly used in footbridges, building piles, highway bridges, construction, ships, lifting machinery, offshore platforms, wind power generation and other fields. The main types of advanced high-strength structural steel include S460, S550, S690, S800, S960, etc. Among them, S690 high-strength structural steel has a wide range of applications, especially suitable for long-span pedestrian bridges, super high-rise buildings and offshore platforms, lifting Mechanical steel structure field.

The mechanical properties of high-strength structural steel are key to its ability to withstand the challenges of extreme conditions. High-strength structural steel profiles have excellent mechanical properties such as yield strength, tensile strength, and elongation at break. The yield strength of S690 is 690MPa, the tensile strength is 770~940 MPa, and the elongation at break is greater than 16%. In Hong Kong construction engineering applications, high-strength structural steel profiles can optimize the design, improve seismic performance, reduce the amount of steel, reduce the overall weight of the steel structure, improve cost-effectiveness, and reduce the carbon footprint.

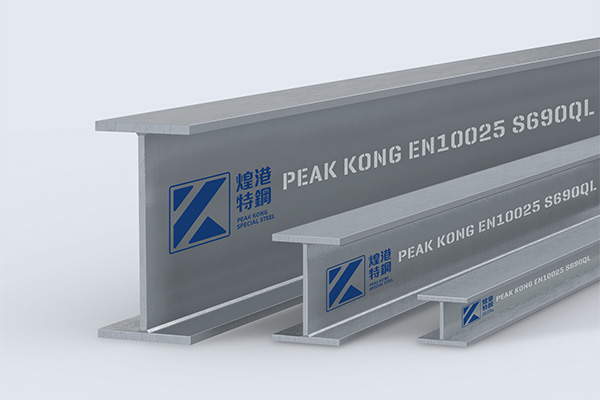

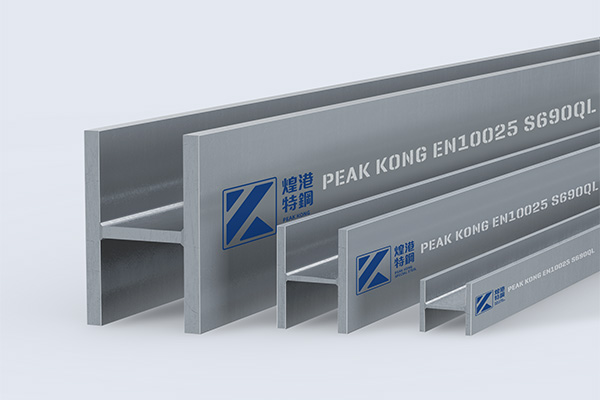

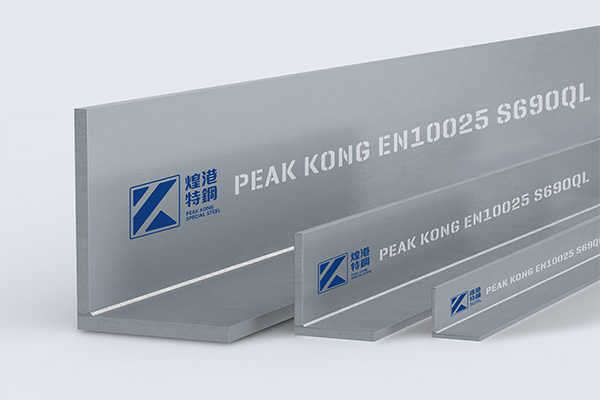

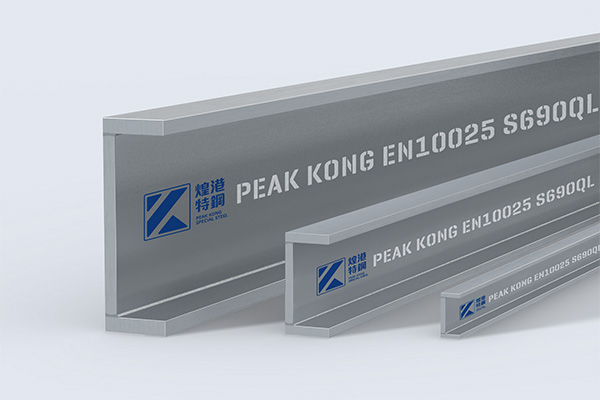

The production and welding technology of high-strength structural steel profiles has always been a difficult problem. Huanggang Special Steel uses automated high-power laser welding complete production lines to produce S460, S550, S690, S800, S960 grades (H-shaped steel, I-beam, channel steel, angle iron , unequal angle iron, T-shaped steel). The material performance is guaranteed, and the welding seam has the same strength as the base metal. The use of advanced high-strength S690 steel profiles can greatly save construction materials, labor requirements and carbon footprint. Typical applications include long-span roof structures and footbridges, large enclosed acoustic enclosures, piles supporting heavily loaded structures and buildings, and support members in highway bridges.

The application prospects of advanced high-strength structural steel are very broad. With the continuous development and exploration of various industries, the demand for high-strength structural steel is also increasing. For example, in the construction of infrastructure such as highways and railways, the application of high-strength structural steel can improve the load-bearing capacity of roads and reduce cracks and settlement problems; in fields such as offshore wind power, high-strength structural steel can reduce the weight of wind turbine towers. It reduces the material cost of the tower, shortens the construction period, and improves the stability and safety of the tower. It is foreseeable that with the continuous updating and upgrading of technology, the application prospects of high-strength structural steel will become more extensive.

Peak Kong Special Steel is committed to the research and development of advanced high-strength steel structural profiles and ultra-high-strength steel structural profiles. Welcome to consult and negotiate.

-

2024-2-20 Stainless steel 904L (1.4539)

2024-2-20 Stainless steel 904L (1.4539) -

2024-1-02 I-beam production technology and application

2024-1-02 I-beam production technology and application -

2024-9-21 Application of S960 steel in bridge engineering

2024-9-21 Application of S960 steel in bridge engineering -

2024-9-29 2.4610 / UNS N06455 Nickel-based alloy hollow structural profiles for applications

2024-9-29 2.4610 / UNS N06455 Nickel-based alloy hollow structural profiles for applications -

2024-9-16 What are some typical applications where 2205 and 1.4436 duplex stainless steels are used?

2024-9-16 What are some typical applications where 2205 and 1.4436 duplex stainless steels are used? -

2024-9-20 What are the advantages of S690 steel in construction engineering compared with conventional steel?

2024-9-20 What are the advantages of S690 steel in construction engineering compared with conventional steel? -

2024-9-29 UNS N06455 structural profile applications

2024-9-29 UNS N06455 structural profile applications