Titanium Grade 7 (Ti Gr 7 / 3.7235 / UNS R52400) is widely recognized for its excellent corrosion resistance, especially in harsh chemical environments. The following is an overview of its application of structural profiles in the field of chemical energy:

Plumbing

– Corrosive Materials Conveying: Pipes used to convey corrosive chemicals, acids and chlorides where traditional materials may fail due to corrosion.

– High-pressure applications: Ideal for high-pressure piping systems in chemical plants, ensuring safety and reliability.

Heat exchanger

– Corrosion Resistant Heat Exchangers: Heat exchangers designed to handle corrosive fluids, maintaining efficiency and durability under extreme conditions.

– Shell and tube design: Suitable for shell and tube heat exchangers, where titanium’s strength and anti-fouling capabilities are advantages.

Storage Tank

– Chemical Storage Tanks: Storage tanks used to store corrosive chemicals, providing long-term durability and leak resistance.

– Pressure Vessels: Pressure vessels used to store gases and liquids to ensure structural integrity in challenging environments.

Reactors and Towers

– Chemical reactors: Reactors used to process corrosive substances, where the chemical resistance of titanium is crucial.

– Distillation columns: Distillation columns used to separate chemical mixtures benefit from the lightweight and strong properties of titanium.

Support Structure

– Equipment architecture: Structural profiles used to support chemical processing equipment, ensuring stability and resistance to environmental factors.

– Brackets and mounts: Brackets and mounts used in a variety of chemical processing equipment provide reliable support without compromising weight.

1. Excellent corrosion resistance: Excellent performance in corrosive environments, especially against acids and chlorides, extending the service life of equipment.

2. High strength-to-weight ratio: Reduces the overall weight of the structure, improves efficiency and eases installation.

3. Ductility and formability: allows complex shapes and designs to adapt to various engineering requirements of chemical facilities.

4. Temperature resistance: Maintains mechanical properties at high temperatures, suitable for high-temperature chemical processes.

5. Reduced Maintenance Costs: Titanium’s durability reduces the need for frequent maintenance, thereby lowering operating costs over time.

-Cost impact: The initial investment in titanium materials may be higher than traditional materials, but the long-term benefits often justify the expense.

Manufacturing expertise: Requires specialized cutting, welding and forming techniques, requiring skilled labor and equipment.

-

2024-9-25 1.459 Super Stainless Steel Structural Profiles

2024-9-25 1.459 Super Stainless Steel Structural Profiles -

2024-9-27 400 / 2.4360 stainless steel structural profiles advantages and applications

2024-9-27 400 / 2.4360 stainless steel structural profiles advantages and applications -

2024-9-21 Application of S690 steel in Hong Kong buildings

2024-9-21 Application of S690 steel in Hong Kong buildings -

2024-9-27 What are the typical applications of 318LN stainless steel structural beams and columns?

2024-9-27 What are the typical applications of 318LN stainless steel structural beams and columns? -

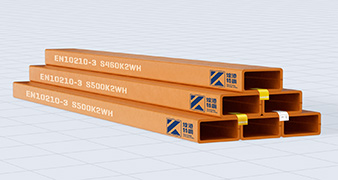

2024-9-19 1.4539 stainless steel hollow structural profile

2024-9-19 1.4539 stainless steel hollow structural profile -

2023-2-15 Laser hybrid welding related technical features

2023-2-15 Laser hybrid welding related technical features -

2024-7-15 Technical delivery conditions for high strength and weather resistant steels

2024-7-15 Technical delivery conditions for high strength and weather resistant steels