The technical delivery conditions for hot finished steel structural hollow sections made from high strength and weather resistant steels are specified in standards like EN 10210-3:2020. This European standard outlines the requirements for hot finished structural hollow sections of non-alloy and fine grain steels that possess enhanced mechanical properties, including high strength and resistance to atmospheric corrosion. Here’s an overview of the key aspects covered by EN 10210-3:2020:

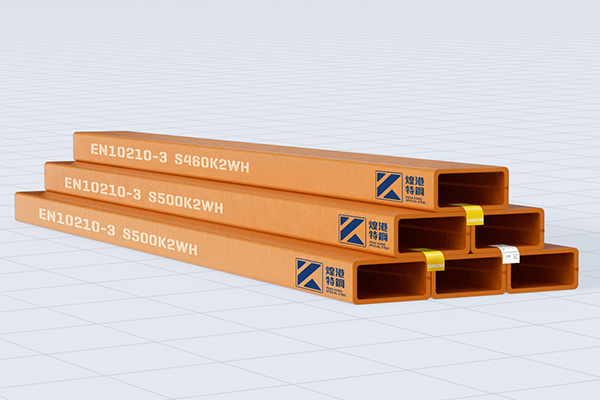

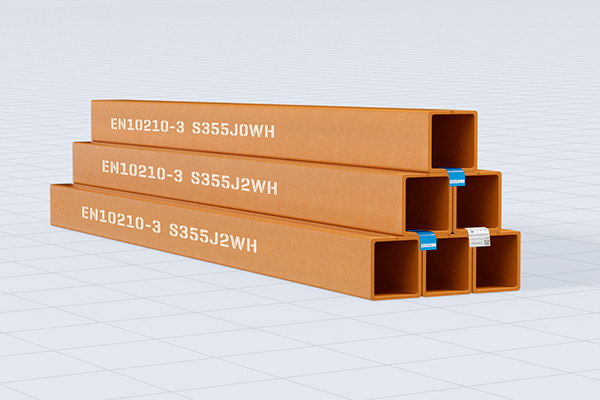

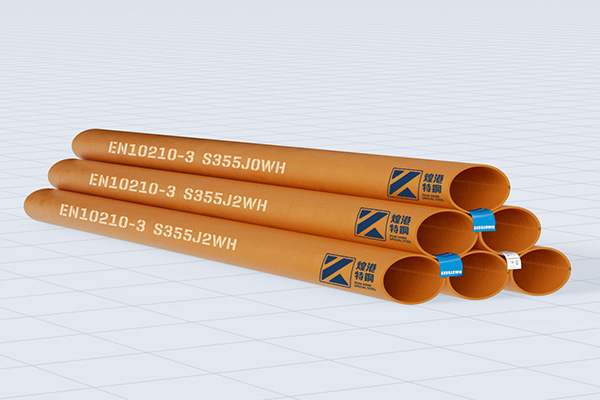

– The standard applies to hot finished structural hollow sections of circular, square, rectangular, or elliptical shapes.

– It includes steels with enhanced properties such as high strength and resistance to atmospheric corrosion (weather resistant steels).

2. Material Requirements:– Specifies grades of steels suitable for hot finished hollow sections, including those with higher yield strengths and improved weather resistance,S500WH.S700WH.

– Ensures compliance with mechanical properties such as yield strength, tensile strength, and impact toughness.

3. Dimensions and Tolerances:– Defines requirements for dimensions, tolerances, lengths, and permissible deviations for structural hollow sections.

– Ensures uniformity in size and shape to facilitate construction and assembly.

4. Testing and Quality Control:– Specifies testing methods and requirements to verify compliance with mechanical properties, including impact testing at specified temperatures.

– Ensures consistent quality and reliability of structural hollow sections for various applications.

5. Applications:– Suitable for use in construction, infrastructure, and engineering projects where high strength and weather resistance are critical.

– Used in applications such as bridges, buildings, offshore platforms and other structures exposed to harsh environmental conditions.

6. Compliance:– EN 10210-3:2020 ensures compliance with European standards and promotes safety, quality and performance in structural applications.

– Provides a framework for manufacturers to produce and supply high-strength, weather-resistant structural hollow profiles that meet industry standards.

-

2024-9-27 926 / 1.4529 Stainless Steel Structural Profiles

2024-9-27 926 / 1.4529 Stainless Steel Structural Profiles -

2024-9-20 Application of Ti Gr 7/3.7235/UNS R52400 Structural Stations

2024-9-20 Application of Ti Gr 7/3.7235/UNS R52400 Structural Stations -

2024-9-21 Application of S960 steel in buildings

2024-9-21 Application of S960 steel in buildings -

2024-9-16 S32205 VS UNS S31803 stainless steel profiles

2024-9-16 S32205 VS UNS S31803 stainless steel profiles -

2024-9-25 2507 super duplex stainless steel in nuclear power of Innovative application

2024-9-25 2507 super duplex stainless steel in nuclear power of Innovative application -

2024-9-29 Alloy 59 / 2.4605 Nickel-Based Alloy Hollow Structural Profiles

2024-9-29 Alloy 59 / 2.4605 Nickel-Based Alloy Hollow Structural Profiles -

2024-9-21 S690 Universal Bearing Piles in civil engineering of Application

2024-9-21 S690 Universal Bearing Piles in civil engineering of Application