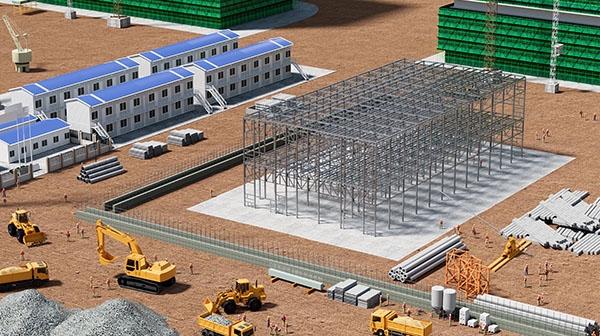

Sheets are primarily used in construction, bridge construction, and in the manufacture of steel structures for general applications. There is a strong demand in this field for carbon and low alloy rolled steels with good weldability, high strength, ductility and crack resistance. For certain applications, structural rolled steel should have improved resistance to atmospheric corrosion.

- Welded H-shaped steel, columns and other support profiles made by cutting steel plates

- Architectural floors and superstructure elements for bridges, high lines and galleries

- Medium and large diameter pipes, used both for utility lines (ducts, chimneys, cables, etc.) and as supports for buildings and bridges

Increased strength and high-strength structural steel plates make it possible to create steel structures that can withstand greater forces or reduce the overall metal consumption under a project by reducing the cross-sectional size of high-strength steel members, compared to conventional materials with the same compressive strength. The use of thermo-mechanically rolled or quenched steel plates for welded columns in modern high-rise buildings can save 20-30% of rolled steel.

construction and renovation

construction and renovation bridge construction

bridge construction Playground Equipment

Playground Equipment Manufacturing of lifting equipment

Manufacturing of lifting equipment- The European standard EN 10025 and its Ukrainian equivalent DSTU EN 10025 “Hot-rolled structural steel products” (six parts) specifies the requirements for hot-rolled non-alloy steels, normalized steels, thermo-mechanically rolled and quenched steels and modified atmosphere steels. Technical delivery conditions Corrosion resistance

- American standards ASTM A36/A36M, ASME A36/A36M, ASTM A283/A283M, ASME A283/A283M, ASTM A514/A514M, ASME A514/A514M, ASTM A572/A572M, ASME A572/A572M, ASTM A573/A573M, ASTM A633/ A633M, ASTM A709/A709M, ASTM A830/A830M, etc., describing specifications for standard-strength, medium-strength, and high-strength carbon, low-alloy, and alloy structural steel rolled materials

- Canadian Structural Steel Standard CSA-G 40.21

- Japanese standards for rolled steel for general structures (including welded structures) JIS G 3101, JIS G 3106

- Ukrainian and CIS standards DSTU 8803/GOST 14637, GOST 1577, DSTU 8541/GOST 19281, DSTU 8539/GOST 27772, DSTU 7806/GOST 4543, DSTU 8817/GOST – 11650 -97 and other structural steel specifications and regulations

Some bridge construction standards also impose requirements on the surface quality of shot blasting panels.

| Dimensions are hight Require: |

Thickness: 4-200 mm, Width: 1500-3800 mm, Length: <20000 mm |

| weight | <20 tons |

| Steel type hight demand |

S235JR, S235J0, S235J2, S275JR, S275J0, S275J2, S355JR, S355J0, S355J2, S355K2, S355N, S355M, S355ML, S420M, S420ML, S460M, S460ML, S460Q, S460QL, S460QL1, S500Q, S500QL, S500QL1, S550Q, S550QL, S550QL1, S620Q, S620QL, S620QL1, S690Q, S690QL, S690QL1, S235J0W, S235J2W, S355J0WP, S355J2WP, S355J0W, S355J2W, S355K2W, A36/A36M, 36, 50, 50W, 1045, St3ps, St3sp, St4ps, St4sp, St5ps, St5sp, 15ps, 15sp, 20, 25, 30, 35, 40, 45, 09G2, 09G2S, 10ХSND, 15HSND, etc |

| delivery conditions | Hot rolled, normalized rolled or normalized, thermomechanically rolled, quenched and moved |

- Hot rolling is a metal processing process in which metal is deformed at high temperatures and then air cooled. Both the rolling temperature and the rolling finish temperature are within the austenite recrystallization temperature range and exceed typical normalizing temperatures.

- Annealing is a heat treatment process outside the rolling line. It heats the steel to above the phase transformation temperature and then slowly maintains and cools it in the furnace. After annealing, the steel acquires higher ductility and lower hardness. There are different types of annealing namely partial annealing, complete annealing, low temperature annealing, diffusion annealing and recrystallization annealing. If the material cools in air rather than in a furnace after heating, the process is called normalizing. This heat treatment increases the strength of the steel compared to annealed steel.

- Normalizing rolling is a deformation process of steel at high temperatures. Full deformation occurs at normalizing temperature and austenite is completely recrystallized.

- Quenching and tempering are heat treatment processes that improve the strength of steel. Quenching involves heating to a given temperature (over Ас3), holding and cooling at high speed using various media (water, oil, ether, etc.) In order to release the internal stress after quenching, the rolled steel is tempered to a temperature as required performance control.

- Thermomechanically Controlled Process (TMCP) is a technology that provides strict temperature and deformation control during hot deformation in rolling mills. No other treatment process offers properties like TMCP.

-

2024-9-19 How do the corrosion resistance characteristics of UNS S32570 and 1.4410 stainless steel structural profiles compare?

2024-9-19 How do the corrosion resistance characteristics of UNS S32570 and 1.4410 stainless steel structural profiles compare? -

2024-9-15 Why choose 1.4301 VS 1.4307 stainless steel?

2024-9-15 Why choose 1.4301 VS 1.4307 stainless steel? -

2024-9-16 Alloy 718/2.4668/UNS N07718 Structural Stations applications

2024-9-16 Alloy 718/2.4668/UNS N07718 Structural Stations applications -

2024-9-25 Stainless Steel 430/1.4016 Structural Profiles

2024-9-25 Stainless Steel 430/1.4016 Structural Profiles -

2024-9-21 S690 Universal Bearing Piles in civil engineering of Application

2024-9-21 S690 Universal Bearing Piles in civil engineering of Application -

2024-9-19 1.4539 stainless steel hollow structural profile

2024-9-19 1.4539 stainless steel hollow structural profile -

2024-9-16 S32205 VS UNS S31803 stainless steel profiles

2024-9-16 S32205 VS UNS S31803 stainless steel profiles