Laser welding is a well-proven technology in the automotive industry, but little is known about laser welding of stainless steel profiles. However, laser welding stainless steel profiles has great advantages compared to other materials.

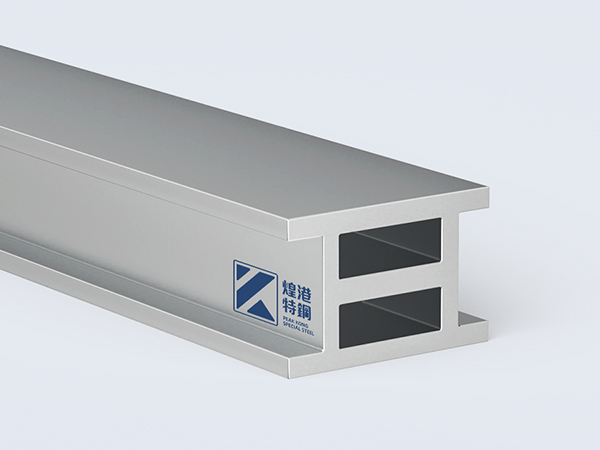

At first, we only produced simple profile geometries, such as stainless steel T-shaped steel, stainless steel H-shaped steel and stainless steel I-beam. Huanggang Special Steel has systematically added more profiles, and now stainless steel angle steel and stainless steel channel steel complete the product series of stainless steel structural profiles.

As Peak Kong Special Steel’s laser welded profiles have received very enthusiastic feedback in the market, architects have even started specifying the sharp edge finish of laser welded profiles in their projects and tenders.

Peak Kong Special Steel’s sharp square and rectangular hollow profiles have become an established and recognized standard in the curtain wall industry. This execution is only possible with laser technology, as the weld beads produced are so small that they are almost imperceptible.

Most laser welded profiles are made from the common austenitic stainless steels 304/304L and 316/316L as well as 316Ti. In addition, many other stainless steel grades are also suitable for laser technology, such as ferritic stainless steels, duplex stainless steels, heat-resistant stainless steels or high-alloy stainless steels, but not all grades are compatible with lasers, for example, martensitic steels are not suitable.

Peak Kong Special Steel also has laser welding machines designed and manufactured individually for special profiles:

3D laser welding is a technology that can weld large parts. For example, there are complex curved parts with multiple welds. This technology also makes it possible to weld profiles with variable cross-sections. High-tech laser welding machines are able to weld hot-rolled or extruded preforms into new complex profile geometries.

In addition, the five-axis laser robot can also come with the GMAW (Gas Metal Arc Welding) process. Therefore, hybrid welding is also possible. This combined welding technology puts GMAW ahead of laser welding and brings several advantages:

- Laser welding profiles of duplex stainless steel can be achieved without reducing corrosion resistance.

- Different raw materials and their combinations can be laser welded (e.g. hot rolled and extruded profiles can be welded together)

- Bypass zero gaps (possible gaps between semi-finished materials will be closed with filler metal)

Another laser welding equipment of Peak Kong Special Steel is the low-impact laser. It is a dedicated machine for the low power range and can weld small and delicate profiles with very little deformation. This type of laser welding also does not produce welding spatter. Peak Kong Special Steel takes advantage of this to weld pre-polished metal strips to beautiful profiles with high-end surfaces without damaging them.

Compared with other technologies, laser technology has some advantages when producing stainless steel profiles:

- less distortion

- Tighter tolerances

- higher productivity

- smaller weld bead

- Significantly tighter tolerances

- No minimum quantity

- Design flexibility

- wider size range

- Significantly tighter tolerances

- higher productivity

- higher surface quality

- wider size range

In the future, laser welding will also play a key role in the production of high-quality profiles. Today, stainless steel laser welded profiles are already preferred over cheaper hot rolled alternatives due to quality reasons. The greater precision imparted by laser technology makes the processing and installation of stainless steel profiles faster and easier.

-

2024-9-29 N06025 Nickel-based alloy structural profiles

2024-9-29 N06025 Nickel-based alloy structural profiles -

2024-9-20 Ti Gr 7/3.7235/UNS R52400 Application of structural profiles in chemical energy

2024-9-20 Ti Gr 7/3.7235/UNS R52400 Application of structural profiles in chemical energy -

2024-9-15 Weathering steel H-shaped steel

2024-9-15 Weathering steel H-shaped steel -

2024-9-21 Application of S960 steel in buildings

2024-9-21 Application of S960 steel in buildings -

2024-7-16 Advanced high-strength steel 690-laser welding

2024-7-16 Advanced high-strength steel 690-laser welding -

2024-7-10 S960Q/S960QL/S960QL1 Steel: A Comprehensive Guide

2024-7-10 S960Q/S960QL/S960QL1 Steel: A Comprehensive Guide -

2024-9-25 S32760 stainless steel structural profiles advantages

2024-9-25 S32760 stainless steel structural profiles advantages