S960 steel is a high-strength structural steel that offers excellent mechanical properties, making it suitable for various applications in industries such as construction, manufacturing, and transportation. Welding is a crucial process in working with S960 steel, as it allows for the joining of different components to create complex structures. peakkong will explore the key aspects of S960 steel welding, including techniques, challenges, and best practices.

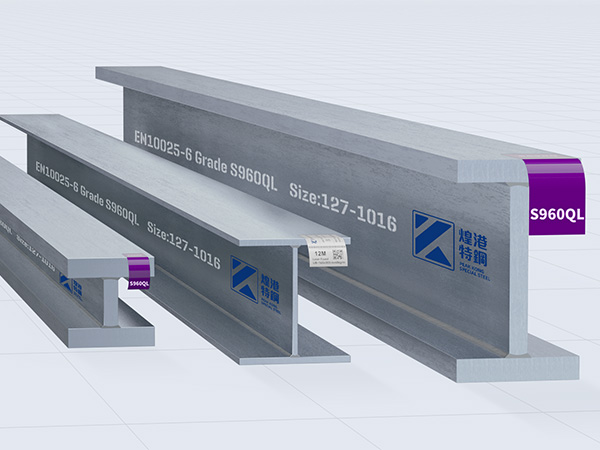

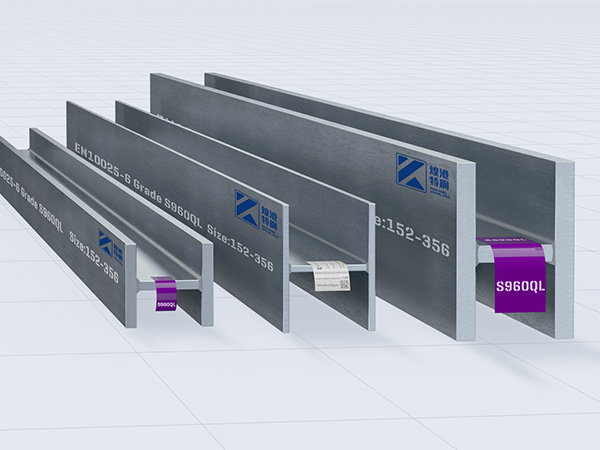

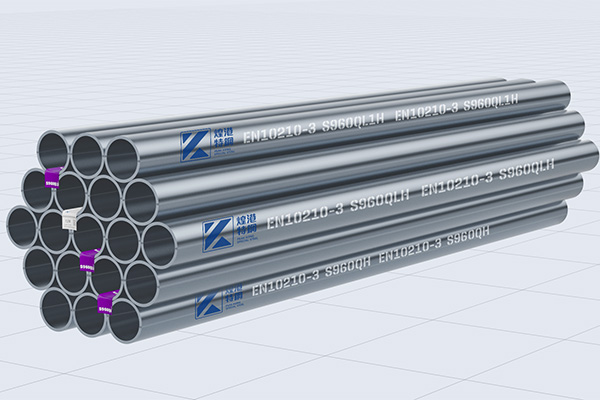

S960 steel belongs to the EN 10025-6 standard, which specifies high-yield strength structural steels. It is characterized by its exceptional strength, durability, and resistance to wear and tear. The steel is commonly used in heavy-duty applications where structural integrity is paramount.

When it comes to welding S960 steel, several techniques can be employed, depending on the specific requirements of the project. Here are some commonly used welding methods:

Manual Metal Arc Welding (MMA)MMA, also known as shielded metal arc welding or stick welding, is a popular technique for welding S960 steel. It involves the use of a consumable electrode coated with flux, which melts during the welding process to create a protective gas shield. MMA welding is versatile and can be performed in various positions, making it suitable for both field and workshop applications.

Gas Metal Arc Welding (GMAW)GMAW, commonly referred to as MIG/MAG welding, utilizes a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. This method offers high productivity and is often preferred for welding S960 steel in industrial settings. GMAW can be performed with both solid and flux-cored wires, providing flexibility in different welding scenarios.

Laser composite weldingPEAKKONG Special Steel uses laser composite welding for S960 steel. Laser welding requires little heat input, small deformation, and 20mm direct penetration. The main advantage is that no preheating is required. It is the first choice for S960 steel welding.

While S960 steel offers exceptional strength, it presents certain challenges during the welding process. These challenges include:

1. Heat Input ControlS960 steel is sensitive to excessive heat input during welding, as it can lead to the formation of undesirable microstructures and reduced mechanical properties. Therefore, it is crucial to carefully control the heat input by adjusting welding parameters such as current, voltage, and travel speed.

2. Preheating and Interpass TemperaturePreheating the base metal before welding and maintaining appropriate interpass temperatures are essential to prevent the formation of brittle structures and reduce the risk of hydrogen-induced cracking. The specific preheating and interpass temperature requirements may vary depending on the welding technique and the thickness of the S960 steel.

3. Post-Weld Heat TreatmentIn some cases, post-weld heat treatment (PWHT) may be necessary to relieve residual stresses and improve the overall weldment’s mechanical properties. PWHT involves heating the welded structure to a specific temperature and holding it for a certain period, followed by controlled cooling. The exact PWHT parameters should be determined based on the specific welding procedure and the desired properties of the final product.

To ensure successful welding of S960 steel, it is essential to follow some best practices. These include:

1. Proper Weld PreparationThoroughly clean the base metal and remove any contaminants, such as rust, oil, or paint, before welding. This ensures good fusion and minimizes the risk of defects in the weld.

2. Use Suitable ConsumablesSelect welding consumables, including electrodes, wires, and fluxes, that are specifically designed for welding high-strength steels like S960. These consumables should have appropriate mechanical properties and low hydrogen content to minimize the risk of cracking.

3. Control Welding ParametersCarefully adjust welding parameters, such as current, voltage, travel speed, and heat input, to ensure proper fusion and minimize the risk of overheating or underheating the S960 steel.

4. Perform Non-Destructive Testing (NDT)Conduct non-destructive testing, such as ultrasonic or radiographic inspection, to detect any potential defects or discontinuities in the weld.

-

2024-9-20 Application of Ti Gr 2 / 3.7035 Structural Hollow Stations

2024-9-20 Application of Ti Gr 2 / 3.7035 Structural Hollow Stations -

2024-9-15 Introduction to the performance of 1.4301/1.4307 stainless steel

2024-9-15 Introduction to the performance of 1.4301/1.4307 stainless steel -

2024-1-31 Introduction to stainless steel I-beam

2024-1-31 Introduction to stainless steel I-beam -

2024-7-10 S960Q/S960QL/S960QL1 Steel: A Comprehensive Guide

2024-7-10 S960Q/S960QL/S960QL1 Steel: A Comprehensive Guide -

2024-9-20 Laser welding fabrication process of Ti Gr 1 / 3.7025

2024-9-20 Laser welding fabrication process of Ti Gr 1 / 3.7025 -

2024-9-27 926 / 1.4529 stainless steel structural hollow sections

-

2024-9-25 318LN / 1.4462 Duplex Stainless Steel Structural Profiles

2024-9-25 318LN / 1.4462 Duplex Stainless Steel Structural Profiles