S960 steel laser hybrid welding is a cutting-edge technology that combines the benefits of laser welding and hybrid welding techniques to achieve superior weld quality and efficiency. PEAKKONG Special Steel will explore the features, advantages, and applications of S960 steel laser hybrid welding.

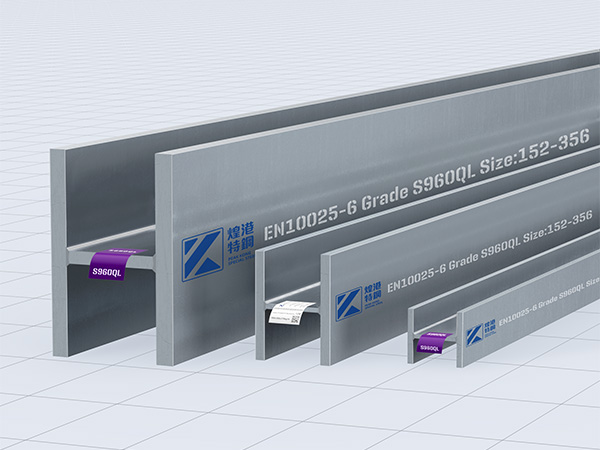

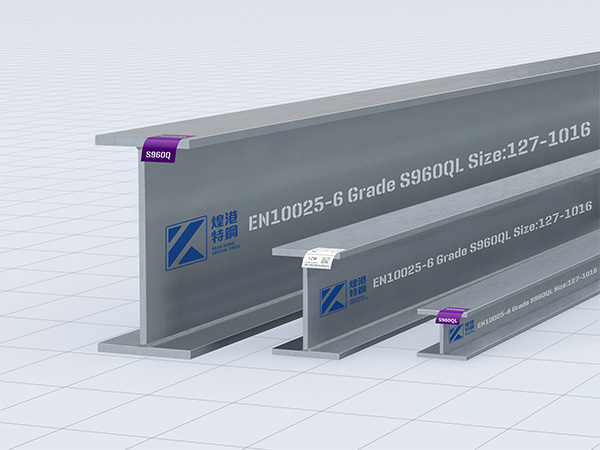

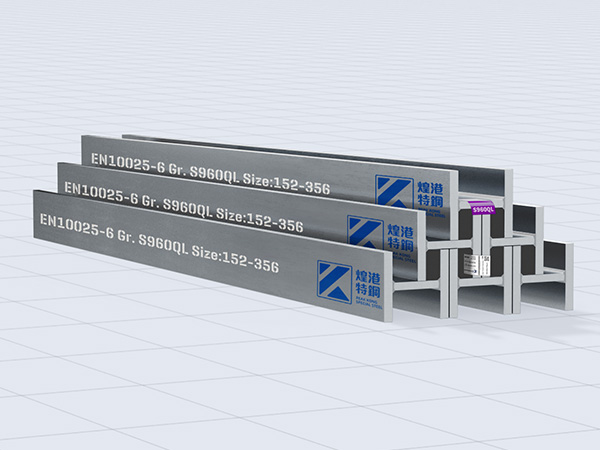

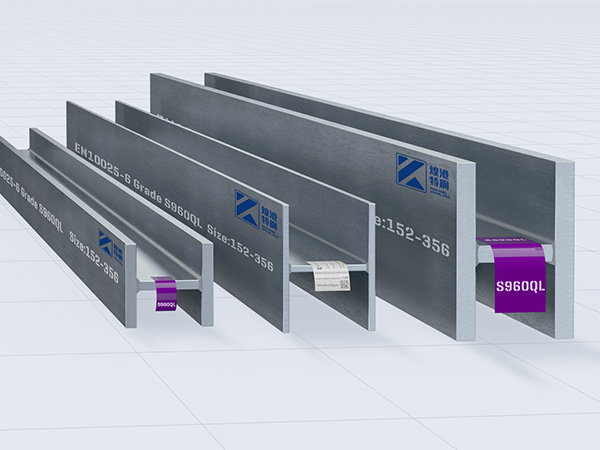

S960 steel is a high-strength, low-alloy structural steel that offers excellent mechanical properties, making it suitable for various demanding applications. It is commonly used in the construction industry for bridges, buildings, and heavy machinery due to its exceptional strength and durability.

Laser hybrid welding is a welding process that combines the advantages of laser welding and arc welding. It involves the use of a laser beam and an arc welding process, such as gas metal arc welding (GMAW) or gas tungsten arc welding (GTAW), to create a hybrid welding technique.

The laser beam provides a concentrated heat source, resulting in a narrow and deep weld penetration. On the other hand, the arc welding process provides better control over the weld pool and filler material deposition. This combination allows for precise control of the welding process, resulting in high-quality welds with reduced distortion and improved productivity.

- 1. Enhanced Weld Quality: S960 steel laser hybrid welding offers superior weld quality with minimal defects, such as porosity and cracks. The precise control over the welding process ensures consistent and reliable welds, meeting the highest quality standards.

- 2. Increased Productivity: The combination of laser and arc welding techniques in S960 steel laser hybrid welding enables faster welding speeds and higher deposition rates. This results in improved productivity and reduced production time, making it an ideal choice for time-sensitive projects.

- 3. Reduced Distortion: S960 steel laser hybrid welding minimizes distortion during the welding process. The concentrated heat input from the laser beam and controlled arc welding process help to prevent excessive heat buildup, resulting in less distortion and warping of the welded components.

- 4. Cost-effective Solution: Despite the advanced technology involved, S960 steel laser hybrid welding offers a cost-effective solution in the long run. The improved productivity and reduced rework contribute to overall cost savings, making it an attractive option for various industries.

S960 steel laser hybrid welding finds applications in a wide range of industries, including:

- 1. Construction: S960 steel is commonly used in the construction industry for structural components, such as beams, columns, and trusses. Laser hybrid welding ensures strong and durable welds, making it suitable for high-rise buildings, bridges, and other infrastructure projects.

- 2. Heavy Machinery: The high-strength properties of S960 steel make it ideal for heavy machinery applications, such as excavators, cranes, and mining equipment. Laser hybrid welding provides reliable welds, ensuring the structural integrity and longevity of these machines.

- 3. Automotive: S960 steel laser hybrid welding is also used in the automotive industry for manufacturing components that require high strength and safety standards. This includes chassis frames, roll cages, and structural reinforcements.

- 4. Offshore and Marine: The offshore and marine industry demands materials that can withstand harsh environments and extreme conditions. S960 steel laser hybrid welding offers excellent corrosion resistance and mechanical properties, making it suitable for offshore platforms, shipbuilding, and marine structures.

-

2024-9-19 Alloy 718/2.4668/UNS N07718 Hollow structural profile applications

2024-9-19 Alloy 718/2.4668/UNS N07718 Hollow structural profile applications -

2024-9-20 What are some of the common structural elements or members fabricated using 1.4404 stainless steel profiles in civil projects?

2024-9-20 What are some of the common structural elements or members fabricated using 1.4404 stainless steel profiles in civil projects? -

2024-9-20 1.4404 stainless steel profiles in construction engineering innovative applications

2024-9-20 1.4404 stainless steel profiles in construction engineering innovative applications -

2024-9-21 S960 steel structures of Fabrication

2024-9-21 S960 steel structures of Fabrication -

2024-9-25 2507 super duplex stainless steel in nuclear power of Innovative application

2024-9-25 2507 super duplex stainless steel in nuclear power of Innovative application -

2024-9-19 UNS N08904 VS 1.4539 stainless steel performance

2024-9-19 UNS N08904 VS 1.4539 stainless steel performance -

2024-9-25 Application of 1.4404 stainless steel structural profiles in civil engineering

2024-9-25 Application of 1.4404 stainless steel structural profiles in civil engineering