S690 steel is a high-strength structural steel commonly used in various industries, including construction, mining, and transportation. Laser welding is a popular method for joining S690 steel due to its numerous advantages, such as high precision, minimal heat input, and reduced distortion. PEAKKONG Special Steel will explore the process of laser welding S690 steel, its benefits, and its applications.

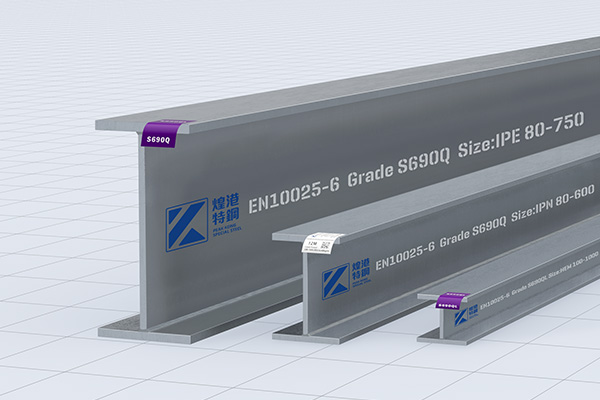

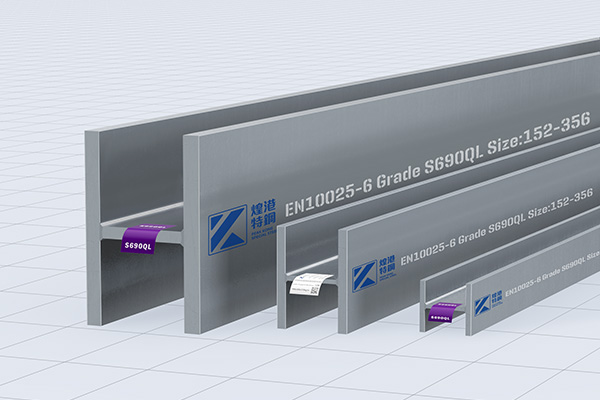

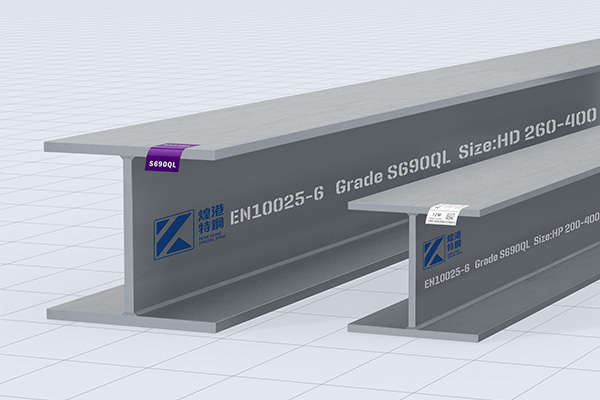

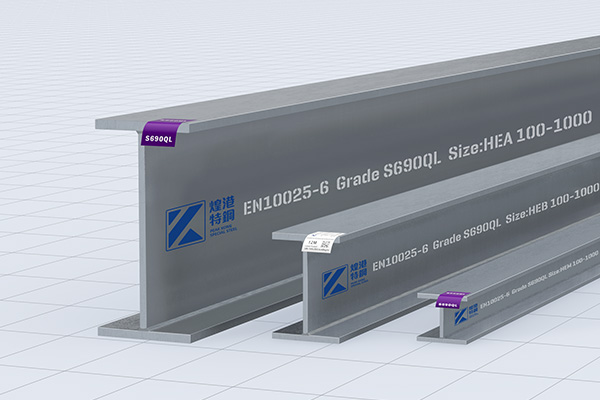

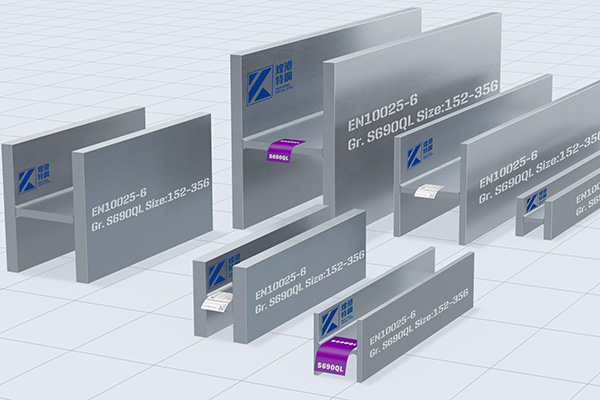

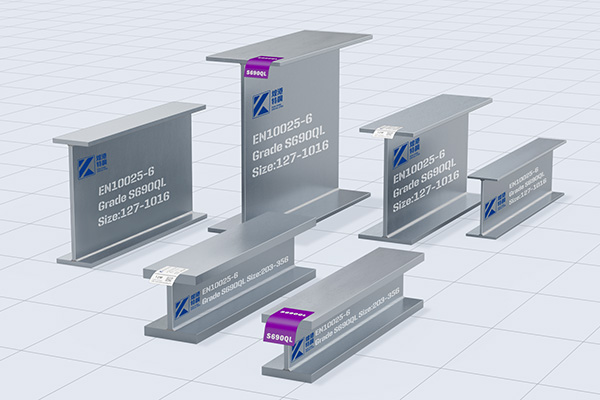

S690 steel is a high-strength, low-alloy structural steel that offers excellent mechanical properties. It is known for its high yield strength, which ranges from 690 to 1100 MPa, depending on the grade. This steel is typically used in applications where weight reduction, durability, and load-bearing capacity are crucial.

Laser welding is a technique that utilizes a high-energy laser beam to melt and fuse the edges of two or more pieces of metal. When it comes to welding S690 steel, laser welding offers several advantages over traditional welding methods. The process involves the following steps:

- 1. Preparation: The surfaces to be welded are thoroughly cleaned and prepared to ensure proper bonding.

- 2. Laser Beam Generation: A high-power laser beam is generated, typically using a solid-state laser or a fiber laser.

- 3. Beam Focusing: The laser beam is focused onto the joint area using lenses or mirrors, resulting in a concentrated heat source.

- 4. Welding: The laser beam rapidly heats the edges of the S690 steel, causing them to melt and form a weld pool. The molten metal solidifies, creating a strong and durable joint.

- 5. PEAK KONG Special Steel automated laser welding equipment directly penetrates 20mm, with a maximum thickness of 60mm (beveling required).

Laser welding offers several advantages when it comes to joining S690 steel:

- 1.High Precision: Laser welding provides precise control over the heat input, resulting in minimal distortion and precise weld bead placement.

- 2.Reduced Heat Affected Zone (HAZ): The concentrated heat source of the laser beam minimizes the HAZ, reducing the risk of material degradation.

- 3.Strong and Durable Joints: Laser welding produces high-quality welds with excellent mechanical properties, ensuring the integrity and strength of the joint.

- 4.Increased Productivity: The high welding speed of laser welding allows for faster production cycles, improving overall productivity.

- 5.Versatility: Laser welding can be used to join S690 steel with various thicknesses and geometries, making it suitable for a wide range of applications.

Laser welded S690 steel finds applications in various industries, including:

- 1. Construction: Laser welding is used to join S690 steel components in the construction of bridges, buildings, and infrastructure projects. The high strength and durability of the welds ensure the structural integrity of these critical structures.

- 2. Mining: S690 steel is commonly used in mining equipment, such as excavators and dump trucks. Laser welding provides reliable and robust welds, ensuring the equipment’s longevity and performance in harsh mining environments.

- 3. Transportation: Laser welded S690 steel is utilized in the manufacturing of heavy-duty transportation vehicles, such as trailers and tankers. The high-strength welds contribute to the overall safety and load-bearing capacity of these vehicles.

- Previous:S960 Steel Laser Welding

- Next:S960 Steel Laser Hybrid Welding

-

2024-9-25 254SMO vs. UNS S31254 Super Stainless Steel for Structural Beams and Columns

2024-9-25 254SMO vs. UNS S31254 Super Stainless Steel for Structural Beams and Columns -

2024-9-25 S32760 stainless steel structural profiles advantages

2024-9-25 S32760 stainless steel structural profiles advantages -

2024-1-31 Introduction to stainless steel I-beam

2024-1-31 Introduction to stainless steel I-beam -

2024-9-27 1.4562 stainless steel hollow structural profile applications

2024-9-27 1.4562 stainless steel hollow structural profile applications -

2024-9-25 UNS N08926 Super Stainless Steel Structural Profiles

2024-9-25 UNS N08926 Super Stainless Steel Structural Profiles -

2024-9-29 Nickel Alloy C4 / 2.4610 Nickel alloy structural profiles for beams and columns

2024-9-29 Nickel Alloy C4 / 2.4610 Nickel alloy structural profiles for beams and columns -

2024-9-27 In what types of applications or environments are 926 (1.4529) stainless steel beams and columns typically used?

2024-9-27 In what types of applications or environments are 926 (1.4529) stainless steel beams and columns typically used?