S690 steel is a high-strength structural steel commonly used in various industries, including construction, mining, and transportation. Laser hybrid welding is a modern welding technique that offers numerous advantages when it comes to joining S690 steel components. PEAKKONG Special Steel will explore the benefits, process, and applications of S690 steel laser hybrid welding.

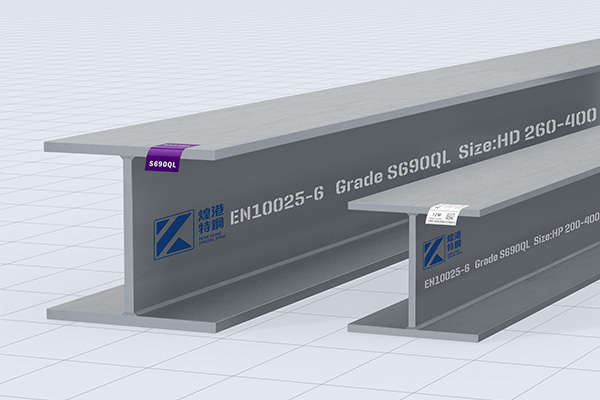

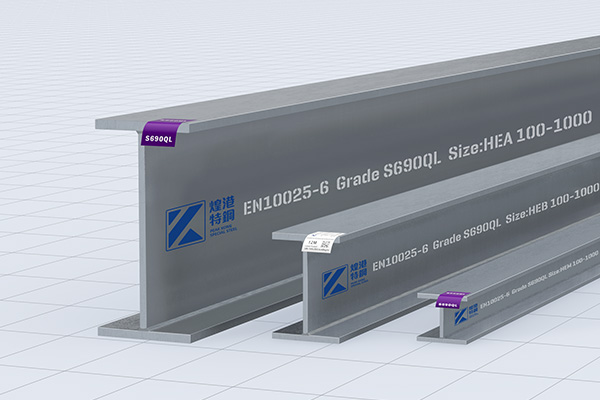

S690 steel is a high-strength, low-alloy structural steel known for its excellent mechanical properties. It is commonly used in heavy-duty applications where strength and durability are crucial. S690 steel offers superior strength, impact resistance, and weldability, making it suitable for demanding environments.

Laser hybrid welding combines the benefits of laser welding and arc welding techniques, resulting in a highly efficient and precise welding process. When it comes to S690 steel, laser hybrid welding offers several advantages:

- 1. High welding speed: Laser hybrid welding allows for faster welding speeds compared to traditional welding methods. This results in increased productivity and reduced production time.

- 2. Narrow heat-affected zone: Laser hybrid welding minimizes the heat-affected zone, reducing the risk of distortion and preserving the material’s mechanical properties.

- 3. Improved weld quality: The combination of laser and arc welding in the hybrid process ensures deep penetration, excellent fusion, and high-quality welds. This results in stronger and more reliable joints.

- 4. Reduced spatter and fumes: Laser hybrid welding produces minimal spatter and fumes, creating a cleaner working environment and reducing the need for post-weld cleaning.

- 5. Deep Penetration: The focused laser beam can achieve deep penetration into the S960 steel, ensuring a strong bond between the welded components. PEAKKONG Special Steel automated laser welding equipment directly penetrates 20mm, with a maximum thickness of 60mm (beveling required).

The laser hybrid welding process involves the simultaneous use of a laser beam and an electric arc to create a weld. Here is a step-by-step overview of the process:

- 1. Preparation: The S690 steel components to be welded are prepared by cleaning and aligning them properly.

- 2. Joint configuration: The joint configuration is determined based on the specific application requirements. Butt joints, fillet welds, or lap joints can be used.

- 3. Fixturing: The components are securely fixed in position using clamps or fixtures to ensure proper alignment during welding.

- 4. Laser beam and arc interaction: The laser beam and electric arc are precisely controlled and directed onto the joint area. The laser beam provides the heat source, while the arc stabilizes the welding process.

- 5. Welding parameters: The welding parameters, such as laser power, arc current, and welding speed, are optimized to achieve the desired weld quality and penetration.

- 6. Cooling and post-weld treatment: After the welding process, the welded joint is allowed to cool naturally or through controlled cooling methods. Post-weld treatments, such as stress relieving or surface finishing, may be applied if required.

S690 steel laser hybrid welding finds extensive applications in various industries. Some notable applications include:

- 1. Construction: S690 steel laser hybrid welding is widely used in the construction of bridges, high-rise buildings, and offshore structures. The high strength and superior weld quality ensure structural integrity and durability.

- 2. Mining equipment: Mining equipment, such as excavators, dump trucks, and drilling rigs, often require the use of S690 steel. Laser hybrid welding ensures reliable and robust joints, capable of withstanding harsh mining environments.

- 3. Transportation: S690 steel laser hybrid welding is employed in the manufacturing of heavy-duty transportation vehicles, including trailers, tankers, and railway wagons. The lightweight yet strong welds contribute to fuel efficiency and load-carrying capacity.

- 4. Energy sector: S690 steel laser hybrid welding plays a vital role in the energy sector, particularly in the construction of power plants, wind turbines, and offshore platforms. The high-strength welds withstand extreme weather conditions and mechanical stresses.

-

2024-9-27 What are the advantages of using 318LN (1.4462) duplex stainless steel structural profiles?

2024-9-27 What are the advantages of using 318LN (1.4462) duplex stainless steel structural profiles? -

2024-9-19 1.4462 stainless steel structural Beams and columns

2024-9-19 1.4462 stainless steel structural Beams and columns -

2024-9-19 904L stainless steel hollow profile

2024-9-19 904L stainless steel hollow profile -

2024-9-16 UNS S31803 stainless steel Hollow Sections and steel profiles of innovative applications

2024-9-16 UNS S31803 stainless steel Hollow Sections and steel profiles of innovative applications -

2024-9-29 What are the typical applications of Alloy 59 / 2.4605 nickel-based alloy hollow structural profiles?

2024-9-29 What are the typical applications of Alloy 59 / 2.4605 nickel-based alloy hollow structural profiles? -

2024-9-24 310S stainless steel performance introduction

2024-9-24 310S stainless steel performance introduction -

2024-9-20 How does high-strength S690 steel play a role in the construction field?

2024-9-20 How does high-strength S690 steel play a role in the construction field?