S460 is a high-strength structural steel grade defined in the EN 10025-6 standard. Here are some key characteristics and considerations regarding S460 high strength structural steel sections:

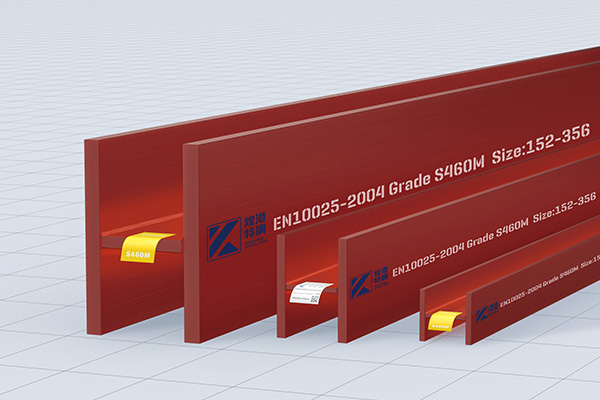

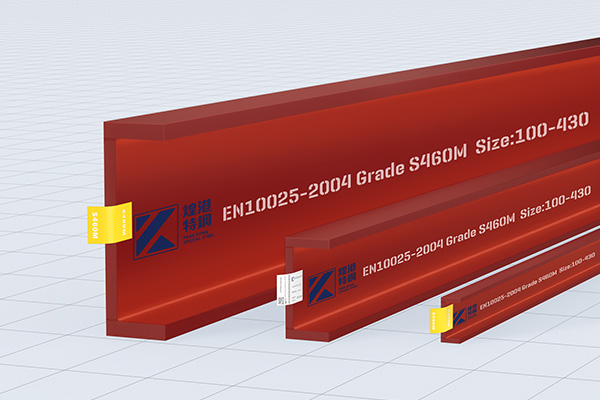

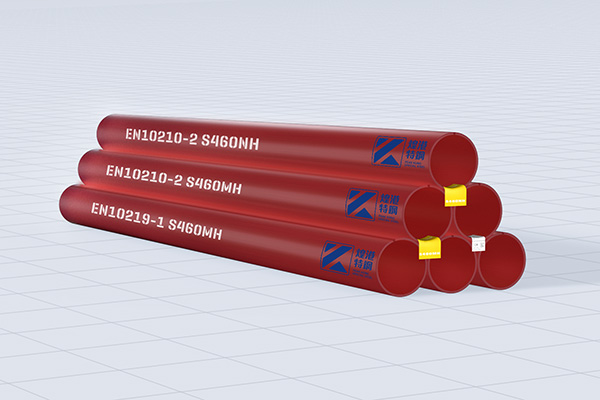

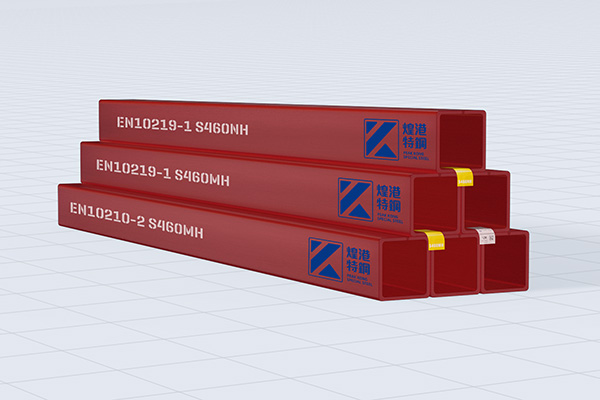

Peakkong Special Steel introduces S460 grade (H-beam, I-beam, channel, angle, square tube, flat tube, steel pipe) to the market.

High Yield Strength: S460 steel typically has a minimum yield strength of 460 MPa, which qualifies it as a high-strength steel suitable for structural applications requiring robust performance.

Good Toughness: Despite its high strength, S460 steel maintains good toughness and ductility, allowing it to absorb energy during impact and resist brittle fracture.

Weldability: S460 steel can be welded using conventional welding methods suitable for high-strength steels. Preheating and controlled heat input may be necessary to ensure proper weld quality and avoid issues such as hydrogen-induced cracking.

Formability: S460 steel is generally suitable for cold forming operations, although it is stiffer than lower strength steels and requires more force during bending and forming processes.

Applications: S460 high-strength structural steel sections are used in a variety of applications where high load-bearing capacity and durability are required. This includes construction of bridges, buildings, offshore structures, and machinery components.

Beams: Used for structural support in buildings and bridges.

Columns: Provide vertical support in structural frameworks.

Channels: Used in framing and support structures.

Angles: Provide bracing and support in construction.

S460 steel sections are produced according to European standards, primarily EN 10025-6. This standard specifies the technical delivery conditions for flat and long products of high yield strength structural steels in the quenched and tempered condition.

Structural Design: Designers should consider the specific mechanical properties of S460 steel, including its yield strength, to optimize structural performance and ensure safety.

Fabrication Techniques: Proper handling and fabrication practices should be employed to maintain the integrity of S460 steel sections during cutting, welding, and forming processes.

Surface Treatment: Depending on the application and environmental conditions, surface treatment such as painting or galvanizing may be required to enhance corrosion resistance and durability.

-

2024-9-27 C22 / 2.4602 nickel-based alloy structural profiles

2024-9-27 C22 / 2.4602 nickel-based alloy structural profiles -

2024-9-27 What are the typical applications of 318LN stainless steel structural beams and columns?

2024-9-27 What are the typical applications of 318LN stainless steel structural beams and columns? -

2024-9-25 SMO254 vs. 1.4547 Super Stainless Steel for Structural Applications

2024-9-25 SMO254 vs. 1.4547 Super Stainless Steel for Structural Applications -

2024-9-16 316 vs 1.4401 stainless steel structural beams and columns

2024-9-16 316 vs 1.4401 stainless steel structural beams and columns -

2024-9-25 318LN / 1.4462 Duplex Stainless Steel Structural Profiles

2024-9-25 318LN / 1.4462 Duplex Stainless Steel Structural Profiles -

2024-9-20 What are some of the common structural elements or members fabricated using 1.4404 stainless steel profiles in civil projects?

2024-9-20 What are some of the common structural elements or members fabricated using 1.4404 stainless steel profiles in civil projects? -

2024-9-16 2507 super duplex stainless steel Hollow Structural Sections

2024-9-16 2507 super duplex stainless steel Hollow Structural Sections