High-strength steel (HSS) and advanced high-strength steel (AHSS) are both significant materials in engineering and manufacturing due to their enhanced mechanical properties compared to conventional steels. Here are the key properties and characteristics of each:

Strength:HSS typically refers to steel grades with yield strengths ranging from 350 MPa to 550 MPa, which is significantly higher than traditional mild steels (usually around 250 MPa).

Toughness:Despite their higher strength, HSS maintains good toughness and ductility, allowing them to absorb energy in impact situations and resist brittle fracture.

Formability:HSS can be formed and welded using conventional methods, though it may require more force due to its higher strength. Cold forming is common, and it can be shaped into complex parts.

Weight Reduction:Using HSS allows for the design of lighter structures while maintaining or improving overall performance, which can lead to fuel efficiency improvements in automotive and aerospace applications.

Applications:HSS finds use in automotive components (chassis, crash structures), construction and infrastructure (bridges, high-rise buildings), and industrial equipment where weight savings and increased strength are critical.

Higher Strength:AHSS refers to steel grades with even higher yield strengths, typically ranging from 500 MPa to 2000 MPa or more, achieved through alloying elements and advanced manufacturing processes.

Excellent Formability:AHSS maintains high levels of formability, allowing for complex shapes and deep drawing processes. This is achieved through processes like hot forming, cold forming, and tailored blanks.

Improved Ductility:AHSS exhibits improved ductility compared to conventional HSS, which helps in maintaining integrity during forming and in service, as well as in absorbing impact energy.

Variety of Types:AHSS includes different types such as dual-phase (DP), transformation-induced plasticity (TRIP), complex phase (CP), and martensitic (MS) steels, each tailored for specific applications and performance requirements.

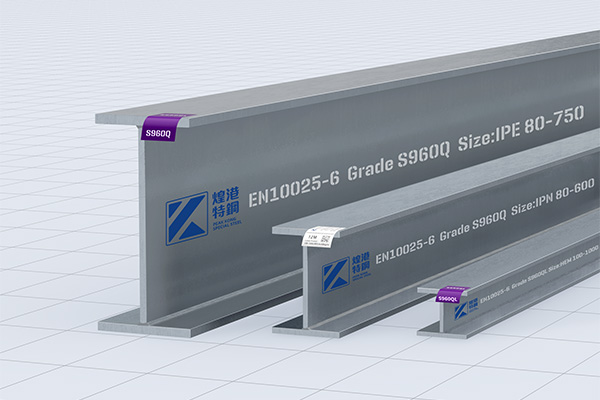

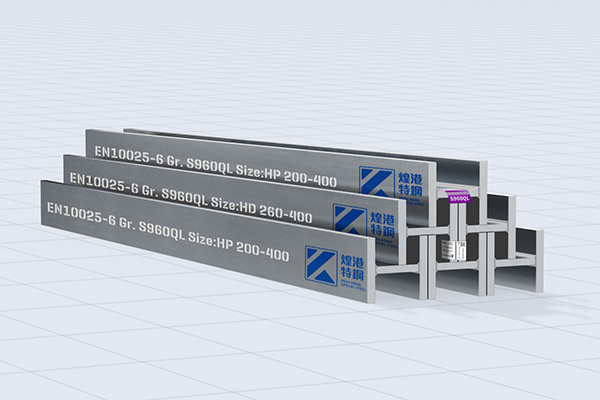

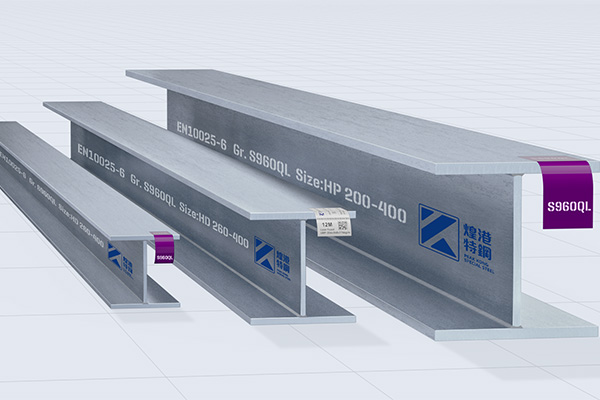

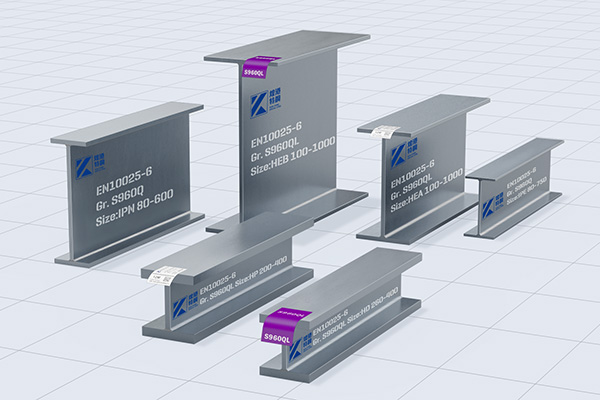

Applications:Bridges/Gymnasiums/High-rise buildings/Noise screens/Offshore platforms, mainly with high bearing capacity, large span, and reduced building weight.

-

2024-9-24 310S stainless steel hollow structural Sections

2024-9-24 310S stainless steel hollow structural Sections -

2024-7-10 S960 Steel Laser Welding

2024-7-10 S960 Steel Laser Welding -

2024-9-29 Alloy 602 CA / 2.4633/N06025 Nickel-based alloy structural profiles for beams and columns

2024-9-29 Alloy 602 CA / 2.4633/N06025 Nickel-based alloy structural profiles for beams and columns -

2024-9-16 316L VS. 1.4404 Stainless Steel Structural Classification and Applications:

2024-9-16 316L VS. 1.4404 Stainless Steel Structural Classification and Applications: -

2024-9-16 UNS S31803 stainless steel of Introduction to the performance

2024-9-16 UNS S31803 stainless steel of Introduction to the performance -

2024-9-27 400 / 2.4360 Stainless Steel Hollow Structural Profiles

2024-9-27 400 / 2.4360 Stainless Steel Hollow Structural Profiles -

2024-9-16 What are some typical applications where 2205 and 1.4436 duplex stainless steels are used?

2024-9-16 What are some typical applications where 2205 and 1.4436 duplex stainless steels are used?