In November 2024, Peak Kong Special Steel achieved another industry milestone by successfully completing the welding and structural fabrication of high-strength steels S690QL and S960QL. This breakthrough marks a new level of excellence in high-strength steel welding and provides strong technical support for the global high-end steel market.

S690QL and S960QL are one of the most widely used ultra-high-strength steels on the market. They are widely used in bridges, large buildings, marine engineering and heavy machinery due to their excellent strength and toughness. However, the welding of this type of steel is extremely difficult, and the requirements for welding processes and equipment are very strict. Especially in terms of performance control of the heat-affected zone and precise management of welding deformation, these are extremely challenging technical problems.

Through in-depth research and repeated experiments, the Peak Kong Special Steel welding team has successfully overcome these technical bottlenecks and ensured that the strength and toughness of the welds have reached world-class levels. At the same time, the company relies on advanced laser welding equipment and independently developed welding processes to achieve significant improvements in welding efficiency and precision.

In this welding project, Peak Kong Special Steel adopted a self-developed intelligent welding system and strict quality control processes. During the welding process, welding defects are effectively avoided through precise control of welding heat input; at the same time, multi-layer and multi-pass welding technology is used to achieve excellent weld formation and high-quality connection.

In addition, the team also conducted comprehensive performance tests on the welded structure, including tensile strength, fatigue performance and fracture toughness tests. All indicators met or even exceeded international standards. This provides a solid guarantee for the safety and durability of high-strength steel structures.

The success of Peak Kong Special Steel’s high-strength steel welding project not only reflects the company’s technical strength in the field of high-strength steel welding, but also further consolidates its leading position in the high-end steel market. The high-strength steel structure completed this time has been successfully delivered to the customer and will be used in large-scale bridge construction projects to provide customers with more lightweight, high-strength and sustainable steel solutions.

- Previous:The welding team at Peak Kong Special Steel has successfully completed the welding procedure qualification for duplex stainless steel and super duplex stainless steel 2205/2507.

- Next:Peak Kong Special Steel cooperates with the National Steel Structure Engineering Technology Research Center of the Hong Kong Polytechnic University to laser composite weld hollow profile structural parts

-

2024-12-06 A warm welcome to the Civil Division of the Hong Kong Institution of Engineers for visiting the Peak Kong Special Steel factory.

2024-12-06 A warm welcome to the Civil Division of the Hong Kong Institution of Engineers for visiting the Peak Kong Special Steel factory. -

2025-1-11 Peak Kong Special Steel Wins APAC-2024 Laser Welding Structural Profile Manufacturer of the Year Award

2025-1-11 Peak Kong Special Steel Wins APAC-2024 Laser Welding Structural Profile Manufacturer of the Year Award -

2024-12-06 Peak Kong Special Steel Showcases Advanced High-Strength Steel Structural Profiles at WCFS International Conference

2024-12-06 Peak Kong Special Steel Showcases Advanced High-Strength Steel Structural Profiles at WCFS International Conference -

2024-8-01 Welcome to the High-Strength Steel Processing Delegation Visiting Our Company

2024-8-01 Welcome to the High-Strength Steel Processing Delegation Visiting Our Company -

2024-12-06 Peak Kong Special Steel participated in the 2024 Singapore Asia Stainless Steel Exhibition.

2024-12-06 Peak Kong Special Steel participated in the 2024 Singapore Asia Stainless Steel Exhibition. -

2025-1-06 Peak Kong Special Steel and Professor Liu Yaopeng’s team from South China University of Technology jointly tested and studied composite hollow structural profiles.

2025-1-06 Peak Kong Special Steel and Professor Liu Yaopeng’s team from South China University of Technology jointly tested and studied composite hollow structural profiles. -

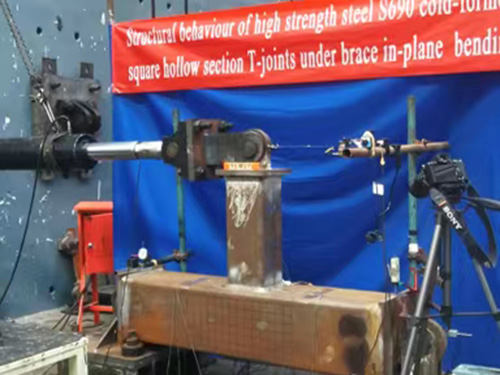

2025-1-06 Peak Kong Special Steel cooperates with the National Steel Structure Engineering Technology Research Center of the Hong Kong Polytechnic University to laser composite weld hollow profile structural parts

2025-1-06 Peak Kong Special Steel cooperates with the National Steel Structure Engineering Technology Research Center of the Hong Kong Polytechnic University to laser composite weld hollow profile structural parts