We have a wide selection of beams available to order, and are made to meet ASTM 276, ASTM A484, ASTM A479/A479M, ASTM 1069 standards. Moreover, the stainless steel beams are used in a variety of industries and applications. The most common industries are food, chemical, pharmaceutical, nuclear, aerospace, and wastewater. Lastly, Stainless steel beams can be extruded, hot rolled or laser fused. The following benefits and features make stainless steel beams a great choice for a wide range of industries and applications.

- High strength

- Corrosion resistant

- Can be sanitized for use in hygienic conditions

ASTM 1069 Laser-Fusion Technique was developed due to a significant void of product offerings, mainly standard A6 sizes. Essentially, anything larger than 6” in height cannot be hot-rolled or extruded due to the chemistry of stainless melt as opposed to carbon. It is similar to traditional welding except for one key difference and that is there is no filler material involved. Three welders are utilized, the largest being a 16kW (x2) fiber solid state laser that when contact is made at the joint, the heat injected is at the most optimal rate which only uses the parent material to bond everything all the way down to the grain structure, no beveling necessary. This makes the section 100% monolithic and a true coalescence of materials. This will give the section a full penetration, homogenous bond up to a 1.25” thick joint. There is virtually zero distortion because the heat input is extremely localized. Mechanical properties are equivalent to or higher than standard carbon shapes and in most cases. Typical yield strengths are in the high 40 KSI range and tensile in the low 90 KSI.

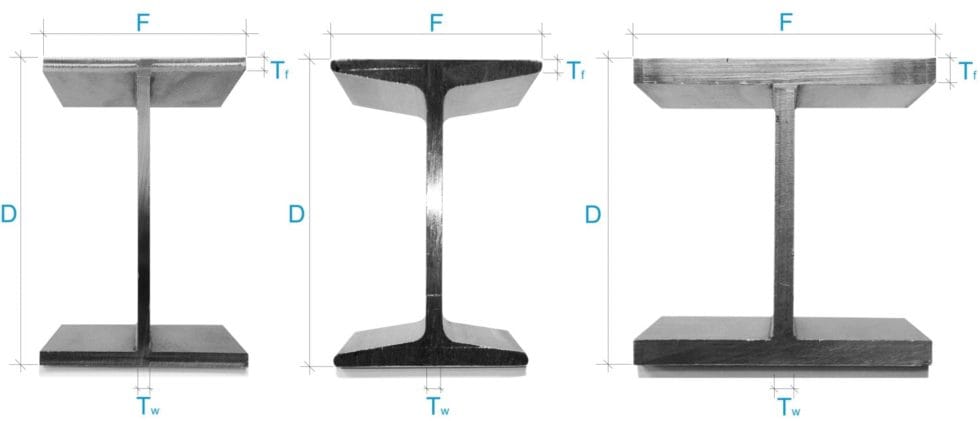

To achieve their unique shape, we design stainless steel beams by welding flat pieces of metal to the strong central support known as the web. The web holds the two flat pieces, known as the flanges, together. Furthermore, the web derives its name from its function of maintaining the structural integrity of the two flanges.This allows both mobility and stability, especially in moving strain.

WebThe web is the center of the beam and is usually graded by thickness. It is the connecting steel that maintains the beams integrity. It connects the two flanges together and helps disperse pressure.

FlangeThe top and flat bottom pieces of steel that receive the brunt of the force. We flatten the flanges to ensure equal pressure dissipation. These two pieces run parallel to each other, and in the case of I-beams, have wing-like extensions.

- 304

- 316

- 2205 Duplex

We name our stainless steel beams after their most distinctive feature – the “I” shape. The I-beam is the universal and most recognizable model, and thus we name the other beams in comparison to this standard.

I BeamThe most common beam in our inventory. The I-beams center web can only be rolled as much as a mill’s equipment can handle (5/8″). The I-Beam is lighter in weight which is why it is used so often. The I-Beam is also a solid piece of metal throughout. It is rolled and manufactured from one part. Can be hot-rolled or laser fused.

H BeamThe H-Beam is stronger than the I-beam, but it requires much more effort to produce in the process. We create H-beams by individually crafting three pieces and then welding them together, instead of rolling them into one piece. This allows each portion to be much stronger because you’re using the milling equipment three times to reinforce material as opposed to using the equipment once to make one item. Overall, the H-Beam is much heavier than the I-beam and can take much more force and pressure.

W BeamOtherwise known as the ‘Wide-Flange’ beam. The W-beam has wide flanges instead of tapered flanges which help with dispersing weight. The wide flange also means that the same material shares the same thickness.

S BeamOtherwise known as the ‘American Standard Beams.’ These are roughly the same thing as I-beams. We have this standard in place because the I-beam is an internationally debated beam with varying dimensions across different countries. Buying the S beam means that you are buying ‘The American Standard’ I-beam, as opposed to a foreign I-Beam standard.

-

2024-9-24 310S stainless steel performance introduction

2024-9-24 310S stainless steel performance introduction -

2024-9-20 Application of Ti Gr 2 / 3.7035 structural profiles in marine industry

2024-9-20 Application of Ti Gr 2 / 3.7035 structural profiles in marine industry -

2024-9-21 S690QH/S690QLH Hollow structural Stations in Hong Kong

2024-9-21 S690QH/S690QLH Hollow structural Stations in Hong Kong -

2024-9-16 What are the typical applications of 316 stainless steel and EN 1.4401 stainless steel?

2024-9-16 What are the typical applications of 316 stainless steel and EN 1.4401 stainless steel? -

2024-3-22 Two official standards for laser welded profiles

2024-3-22 Two official standards for laser welded profiles -

2024-9-16 How does the use of 2205 duplex stainless steel in bridge construction compare to traditional materials like carbon steel?

2024-9-16 How does the use of 2205 duplex stainless steel in bridge construction compare to traditional materials like carbon steel? -

2023-2-10 Laser filler wire welding related technical features

2023-2-10 Laser filler wire welding related technical features