To start this process smoothly:

- Send us a drawing: It can be hand-drawn or in CAD format, whichever you prefer.

- Provide us with information about your project: material grade, quantity, length, surface finish, specific testing requirements, required dimensional tolerances, and any other relevant details.

- Unit B, 9/F, Worldwide Centre, 123 Tung Chau Street, Tai Kok Tsui Kowloon.HongKong

- T: +852-92992995

- E: sales@peakkong.com

- Standard: Corporate standards

- Technology: ISO 15614-11 or ISO 15614-14

- Fabrication Craftsmanship: ISO 15614-11 ,ISO 15614-14

- Steel grade: S355 ,S460 ,S690

- Certificate: EN10204-2.2or3.1B

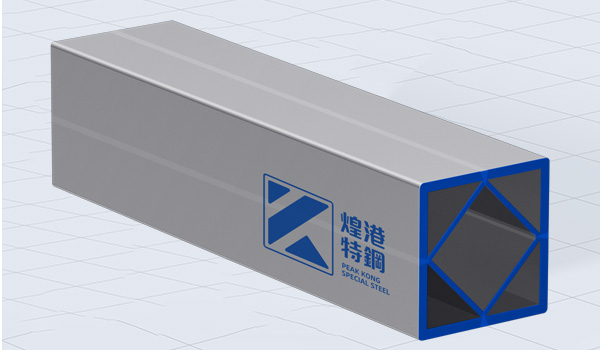

In the construction and engineering fields, composite materials are widely popular for their superior strength and versatility. One such composite material is composite steel profiles, also known as composite steel profiles. These profiles offer a unique combination of strength, durability and lightweight properties, making them ideal for a variety of structural applications.

Composite steel profiles or composite steel profiles are structural elements composed of a combination of steel and steel materials. The steel core provides the necessary strength and rigidity, while the composite material enhances the overall performance and functionality of the profile. This combination results in a lightweight yet strong structural solution that can withstand heavy loads and adverse environmental conditions.

Thanks to the steel core, composite steel profiles have exceptional strength and durability. The steel components have high tensile strength, allowing the profiles to withstand heavy loads without compromising structural integrity. Additionally, the composite materials used in these profiles enhance their corrosion resistance, ensuring long-term durability and minimal maintenance requirements.

Lightweight structureOne of the significant advantages of composite steel profiles is their lightweight nature. Compared to traditional steel profiles, composite steel profiles are significantly lighter while maintaining the same strength level. This lightweight construction not only simplifies the installation process but also reduces the overall weight of the structure, resulting in cost savings and increased energy efficiency.

Design flexibilityComposite steel profiles offer design flexibility, allowing architects and engineers to create innovative and beautiful structures. Composite materials can be molded into a variety of shapes and sizes, enabling complex and unique building designs to be constructed. This versatility opens up a world of possibilities for designers, making composite steel profiles the first choice for modern construction projects.

environmental sustainabilityWith the growing focus on sustainable building practices, composite steel profiles fit perfectly with the green building movement. The lightweight nature of these profiles reduces the carbon footprint associated with transportation and installation. Additionally, the composite materials used in its construction can be sourced from recycled or renewable resources, further reducing environmental impact.

Composite steel profiles are widely used in the construction of buildings and structures. They are commonly used in the fabrication of beams, columns and trusses to provide structural support and stability. The lightweight nature of these profiles simplifies the construction process and reduces the overall weight of the structure, making them ideal for high-rise buildings and large-scale projects.

infrastructure projectsThe superior strength and durability of composite steel profiles make them suitable for infrastructure projects such as bridges, tunnels and rail tracks. These profiles can withstand heavy loads and harsh environmental conditions, ensuring the longevity and safety of your infrastructure. Additionally, its lightweight construction reduces the overall weight of the supporting structure, thereby minimizing the risk of structural fatigue.

Automotive and aerospace industryComposite steel profiles are also used in the automotive and aerospace industries. Their lightweight properties help improve a vehicle's fuel efficiency, reduce emissions and improve overall performance. In the aerospace sector, these profiles are used in the construction of aircraft frames, providing strength and structural integrity while keeping weight to a minimum.

environmental sustainabilityWith the growing focus on sustainable building practices, composite steel profiles fit perfectly with the green building movement. The lightweight nature of these profiles reduces the carbon footprint associated with transportation and installation. Additionally, the composite materials used in its construction can be sourced from recycled or renewable resources, further reducing environmental impact.

PeakKong Special Steel applies Peakkong delivery conditions during the delivery process, and adds that both parties will comply with applicable legal and regulatory requirements and will not engage in any unethical business practices.

The products produced by PeakKong Special Steel.Innovative steel and composite structures The technical delivery conditions of our products meet the respective requirements. Dimensions and tolerances are defined according to the relevant steel material standards. Engineering work complies with the respective standards.

Innovative steel and composite structures Equipped with strapping tags and Peakkong Special Steel product tags to achieve comprehensive traceability and identification. According to the corresponding steel standards, corresponding material certificates will be provided.

Unit B, 9/F, Worldwide Centre, 123 Tung Chau Street, Tai Kok Tsui Kowloon.HongKong.

T: +852-29811161

E: sales@peakkong.com

No. 1 Building 1, No. 6 Xiegang Jinhai Road, Xiegang Town, Dongguan City, Guangdong Province.

T: 0769-82869307

E: admin@peakkong.com

+

+