I-beam is a kind of steel. The unit of the beam is the web and the horizontally symmetrical flanges on both sides of the web, which together form an H-shaped section. I-beams can be classified according to their shape (narrow flange, normal, wide flange and column), manufacturing technology (rolled, welded, riveted or cold formed), design (normal or light), application (general or light) distinguish between industry-specific) and other attributes.

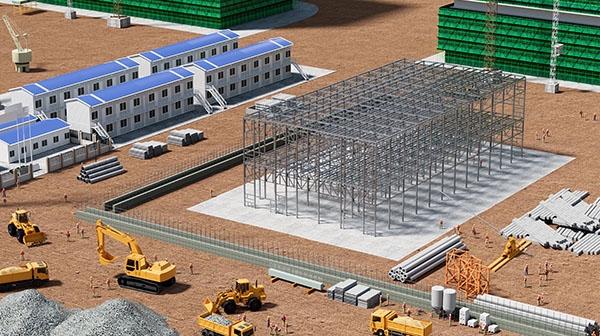

I-beams are mainly used as bridge materials in the construction of buildings, support structures, bridge components, elevated runways, etc. They are also used to reinforce mine shafts and other underground infrastructure. Beams are commonly used in horizontal steel structures to absorb vertical loads and bending stresses. The flanges of I-beams compensate for high deflection forces, and the webs help resist shear forces. Depending on the type of structure and the impacts it will receive, the design engineer selects the steel grade, type, and I-beam cross-section required.

Rolled products of this type are also used in machine building, truck building and other industries.

Welding helps to increase the range and efficiency of beams, allowing flanges and webs to be made of almost any height and width. Welded I-beams can be produced with the required cuts and holes, or they can be made from different steel grades (double steel beams), providing a more adaptable and efficient shape.

construction and renovation

construction and renovation bridge construction

bridge construction Playground Equipment

Playground Equipment Manufacturing of lifting equipment

Manufacturing of lifting equipmentI-beam is a kind of steel. The unit of the beam is the web and the horizontally symmetrical flanges on both sides of the web, which together form an H-shaped section. I-beams can be classified according to their shape (narrow flange, normal, wide flange and column), manufacturing technology (rolled, welded, riveted or cold formed), design (normal or light), application (general or light) distinguish between industry-specific) and other attributes.

The standard range of hot-rolled I-beams includes beam height 100-710mm, wing width 55-440mm, web thickness 3.8-100mm, and beam length 4-12m. Other sizes can also be produced to meet individual customer needs.

The I-beam standard also specifies parameters such as flange thickness, root radius, cross-sectional area and running gauge weight, as well as several other reference values for calculating beam performance.

The main European standards for technical specifications of hot-rolled I-beams are EN 10025-1, EN 10025-2, and EN 10365 for dimensions and weights. The following types of I-beams are manufactured according to these standards:

- IPE – Parallel Flange I-Beam

- HE – wide flange beam

- HL and HLZ – extra wide flange beams

- HD – Wide flange column

- HP and UBP – wide flange load-bearing piles

- UB – Universal Beam

- UC–universal column

- IPN and J – Tapered flange I-section

The main steel grades used for the manufacture of hot-rolled I-beams according to the EN 10025-2 standard are S235JR, S235J0, S235J2, S275JR, S275J0, S275J2, S355JR, S355J0 and S355J2. Normalized, heat treated, quenched and tempered beams can also be produced using steel grades produced according to EN 10025-3, EN 10025-4 and EN 10025-6 standards.

I-beam

I-beam H-beam

H-beamThe most common I-beams are hot-rolled I-beams manufactured by railroad and structural, beam or section rolling mills. The raw materials for the beams are blooms and square billets made of carbon and low-alloy steel, and the required dimensions and tolerances are ensured through special rolling pass designs.

Laser welding of I-beams is another widely used technology for manufacturing I-beams. In this case, steel plates and coils of different grades and sizes are used as raw materials.

-

2024-9-20 Ti Gr 7/3.7235/UNS R52400 Application of structural profiles in chemical energy

2024-9-20 Ti Gr 7/3.7235/UNS R52400 Application of structural profiles in chemical energy -

2024-9-25 Application of 1.4404 stainless steel structural profiles in civil engineering

2024-9-25 Application of 1.4404 stainless steel structural profiles in civil engineering -

2024-9-16 2205 vs 1.4436 Double phase stainless steel structure profile application

2024-9-16 2205 vs 1.4436 Double phase stainless steel structure profile application -

2024-9-19 Alloy 718/2.4668/UNS N07718 in offshore energy applications

2024-9-19 Alloy 718/2.4668/UNS N07718 in offshore energy applications -

2024-9-16 How does the use of 2205 duplex stainless steel in bridge construction compare to traditional materials like carbon steel?

2024-9-16 How does the use of 2205 duplex stainless steel in bridge construction compare to traditional materials like carbon steel? -

2024-9-25 1.4547 Super Stainless Steel for Structural Applications

2024-9-25 1.4547 Super Stainless Steel for Structural Applications -

2024-9-16 Alloy 617 structural profiles for beams and columns

2024-9-16 Alloy 617 structural profiles for beams and columns