The fabrication of S690 steel structures involves several critical steps to ensure quality, accuracy and safety. The following is an overview of key processes and considerations:

Material selection

Grade verification: Ensure that the S690 steel grade number complies with project specifications and standards (e.g. EN 10025-6).

Material Certification: Obtain a material certificate that provides detailed information on mechanical properties and chemical composition.

Design and details

Detailed drawings: Create detailed manufacturing drawings specifying dimensions, tolerances and connection details.

BIM integration: Use Building Information Modeling (BIM) for efficient planning and coordination between different industries.

Cutting and shaping

Precision cutting: Use advanced cutting technology (e.g. plasma cutting, laser cutting) to achieve precise dimensions and minimize thermal deformation.

Forming process: bending, rolling and other methods are used to form the steel components according to the design requirements.

Welding preparation

Edge Preparation: Prepare welding edges by grinding or beveling to ensure proper fusion and strength.

Assembly: Accurately align components before welding to maintain dimensional integrity.

Welding technology

Welding Procedures: Follow established welding procedures in compliance with standards (e.g. AWS, EN ISO 15614) to ensure quality.

Electrode Selection: Use low hydrogen electrodes to minimize the risk of hydrogen induced cracking.

Preheat: If necessary, preheat 150°-200°, especially for thicker sections, to reduce the risk of brittle fracture.

Post-weld treatment

Heat Treatment: Consider post-weld heat treatment (PWHT) to remove residual stresses and improve ductility, especially for critical joints.

Inspection: Use non-destructive testing (NDT) methods (e.g. ultrasonic testing, radiographic testing) to detect welding defects.

Surface treatment

Cleaning: Remove all contaminants (rust, oil, grease) from the surface before applying a protective coating.

Coating Application: Apply protective coatings (e.g. galvanizing, paint) to enhance corrosion resistance, especially in harsh environments.

Assembly and Installation

Pre-assembly: If possible, pre-assemble parts in the shop to ensure fit and reduce on-site assembly time.

Shipping Considerations: Plan the shipping of large parts to ensure they are secured and protected during transport to the construction site.

Quality Control

Inspection Protocol: Implement quality control measures throughout the manufacturing process, including visual and dimensional inspections.

Documentation: Maintain complete documentation of all manufacturing processes, inspections and liability certifications.

The fabrication of S690 steel structures requires careful planning, skilled labor and adherence to quality standards. By following these steps, manufacturers can ensure that the final structure is strong, durable, and meets necessary performance standards.

-

2024-9-29 Nickel Alloy C4 / 2.4610 Nickel alloy structural profiles

2024-9-29 Nickel Alloy C4 / 2.4610 Nickel alloy structural profiles -

2024-9-21 S690 Universal beams to Universal columns

2024-9-21 S690 Universal beams to Universal columns -

2024-9-19 UNS N08904 stainless steel structural profile

2024-9-19 UNS N08904 stainless steel structural profile -

2023-2-10 Laser filler wire welding related technical features

2023-2-10 Laser filler wire welding related technical features -

2024-4-03 High strength steel introduction and solutions

2024-4-03 High strength steel introduction and solutions -

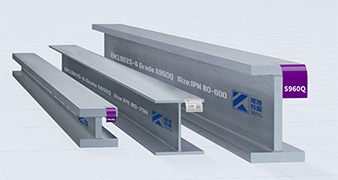

2024-7-03 S960 Ultra-high strength steel structural Sections

2024-7-03 S960 Ultra-high strength steel structural Sections -

2024-7-16 Properties of high-strength steel and advanced high-strength steel-Peak Kong Special Steel

2024-7-16 Properties of high-strength steel and advanced high-strength steel-Peak Kong Special Steel