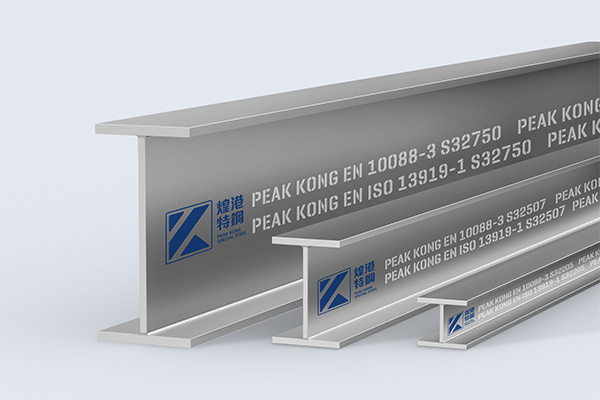

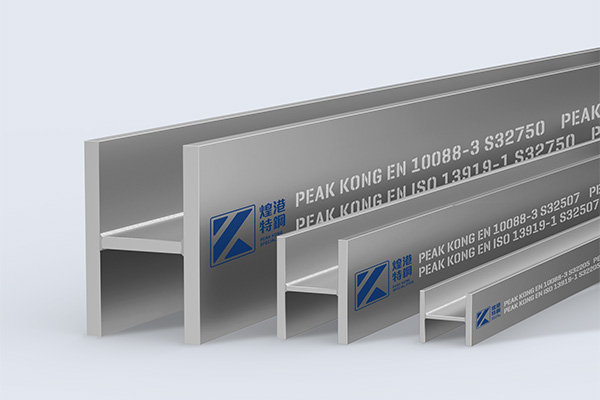

Peak Kong Special Steel has an extensive inventory of Duplex 2304, 2205 and 2507 stainless steel Sections and plate products available to satisfy your challenging corrosion and high strength requirements.

Duplex stainless steel plate contains relatively high levels of chromium (between 18% and 28%) and low to moderate amounts of nickel (between 1.5% and 8%). The high corrosion resistance and excellent mechanical properties of duplex stainless steels can be attributed to their chemical composition and balanced (duplex) microstructure of approximately equal volume percentages of ferrite and austenite.

“Super” duplex grades have enhanced pitting and crevice corrosion resistance when compared with 300-series austenitic stainless steels or conventional duplex alloys. This can be attributed to the enhanced levels of chromium, molybdenum and nitrogen found in these materials. Alloy 2507 is the most common “super” duplex grade.

Many architects, engineers, fabricators and more are very aware of the benefits of using stainless steel for their projects. No other metal can provide the corrosion resistance that stainless steels can, especially in harsh and aggressive environments. Within the stainless steel family are the duplex stainless steels. Duplex stainless steels can provide twice the yield strength of the austenitic and ferritic stainless steel grades. Additionally, they can do that without sacrificing on corrosion resistance and other mechanical and physical properties. So we are seeing people making the switch from 304/L and 316/L to the duplex stainless steeel grades like 2205 and 2507.

One area, where duplex is increasing being used, is in marine environments like boating and on offshore oil rigs. These projects initially may have used 316/L stainless steel. But over time, even 316/L may not hold up under extreme circumstances or if the material is completely submerged in water. Some other areas where duplex stainless steel sections may come into action are for structural supports. Most of the applications are in processing or chemical plants. Both architecture and building design also rely on duplex steel sections for strength and appearance. We can also see duplex stainless steel applications in wastewater and desalination plants, pulp and paper production as well as transportation. Stainless Structurals has had several projects recently involving duplex stainless steel sections.

To produce our duplex steel sections, we developed a “hybrid” laser welding method using laser fusion and arc welding concepts. Our Laser-Hybrid method ensures higher reliability, process control, and repeatability in duplex steel welding. With this method, the corrosion resistance of the weld and heat affected zone is equivalent to the parent material. During this production process, the parent material is fused together just like our standard laser fusion process to form one monolithic structure. The weld seams are minute and barely visible giving the section clean, sharp corners. The fused structure takes on the mechanical properties of the parent material. Furthermore, extensive destructive tests have been performed with results showing the material itself will bend or fracture before the weld area itself will.

Applications: shipbuilding, wind power, nuclear power plants, construction, aerospace, water treatment, chemical industry, mining, offshore platforms, airports and subways.-

2024-9-27 What are the typical applications of 318LN (1.4462) duplex stainless steel structural profiles?

-

2023-12-11 Stainless steel structural profiles

2023-12-11 Stainless steel structural profiles -

2024-9-19 How do the corrosion resistance characteristics of UNS S32570 and 1.4410 stainless steel structural profiles compare?

2024-9-19 How do the corrosion resistance characteristics of UNS S32570 and 1.4410 stainless steel structural profiles compare? -

2024-9-25 SMO254 vs. 1.4547 Super Stainless Steel for Structural Applications

2024-9-25 SMO254 vs. 1.4547 Super Stainless Steel for Structural Applications -

2024-9-20 1.4404 stainless steel in innovative applications in bridges

2024-9-20 1.4404 stainless steel in innovative applications in bridges -

2024-9-27 926 / 1.4529 stainless steel beams and columns

2024-9-27 926 / 1.4529 stainless steel beams and columns -

2023-12-12 Stainless steel laser welding profile knowledge

2023-12-12 Stainless steel laser welding profile knowledge