To start this process smoothly:

- Send us a drawing: It can be hand-drawn or in CAD format, whichever you prefer.

- Provide us with information about your project: material grade, quantity, length, surface finish, specific testing requirements, required dimensional tolerances, and any other relevant details.

- Unit B, 9/F, Worldwide Centre, 123 Tung Chau Street, Tai Kok Tsui Kowloon.HongKong

- T: +852-92992995

- E: sales@peakkong.com

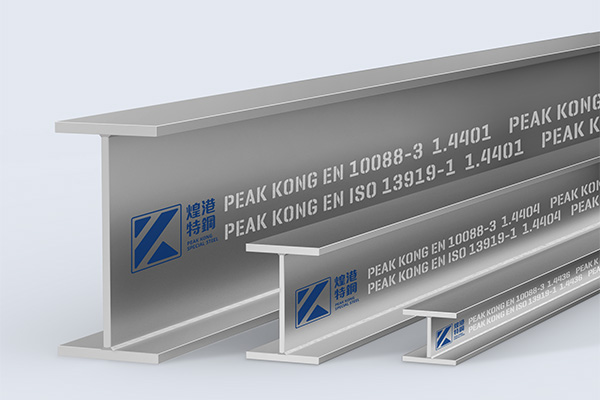

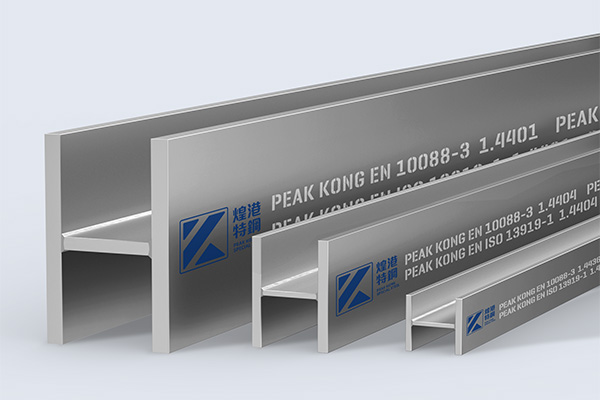

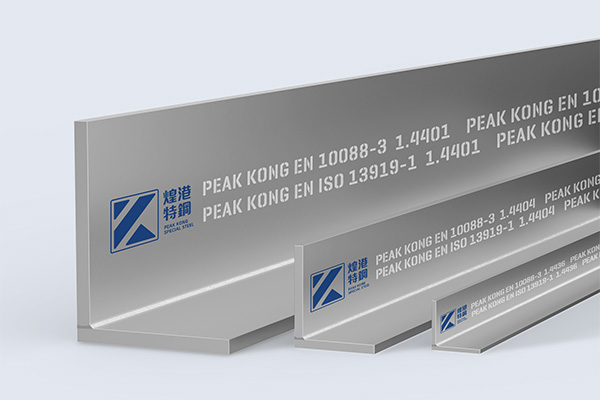

- Standard: EN 10088-3, EN10365, DIN1025

- Technology: ISO 15614-11 or ISO 15614-14

- Fabrication Craftsmanship: ASTM A1069, EN 13919

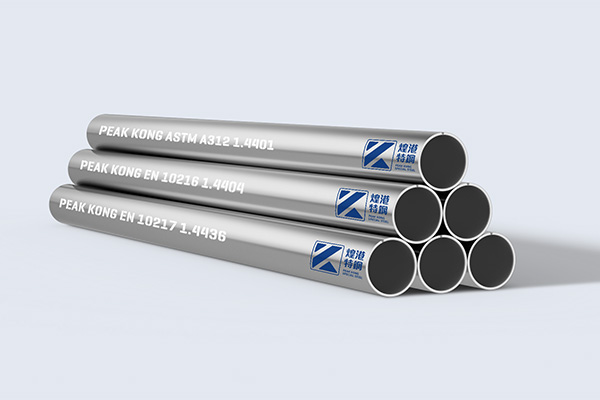

- Steel grade: 1.4301, 1.4307, 1.4401, 1.4404, 1.4436, 1.4507

- Tolerance: EN 10056-2:1993, EN10088-3

- Certificate: According to EN 10204 - Type 2.2 or 3.1b

Laser welding is our most popular production method because it is so efficient, and it offers nearly limitless capabilities and design options. Laser welded sections are produced by welding individual components together, creating a complete section. The pieces are typically flat laser cut strips, but may also be pre-fabricated solids, hollows or other shapes. The joints are created with powerful lasers without any filler material, producing a minute weld bead.

Virtually all commercially available carbon and stainless steels can be laser welded along with the appropriate approvals and certifications. homogeneous welds are easily attainable through a depth of 20mm. Laser welded sections can be produced in carbon steel, stainless steel and duplex steel profiles, among others. Laser welding is a type of laser fusion but does not use any filler material in its process.

Laser welded stainless Sections generally have a better surface finish than extruded or hot rolled products because the raw components are processed from high quality hot rolled plate or from cold drawn flats. Upon being laser welded, the sections are straightened, bead blasted and passivated in an acid solution.

-

ASTM International:A1069/A1069M-11

Standard SpecIfication For Laser-Fused Stainless Steel Bars,Plates and shapes

-

Standard DIN EN ISO 13919-1:1996

Welding — Electron and laser-beam welded joints — Guidance on quality levels for imperfections — Part 1: Steel

- bigger dimension range

- significant tighter tolerances

- higher productivity

- higher surface quality

Applications: shipbuilding, wind power, nuclear power plants, construction, aerospace, water treatment, chemical industry, mining, offshore platforms, airports and Mtr.

PeakKong Special Steel applies Peakkong delivery conditions during the delivery process, and adds that both parties will comply with applicable legal and regulatory requirements and will not engage in any unethical business practices.

The products produced by PeakKong Special Steel.Titanium alloy structural profiles The technical delivery conditions of our products meet the respective requirements. Dimensions and tolerances are defined according to the relevant steel material standards. Engineering work complies with the respective standards.

Titanium alloy structural profiles Equipped with strapping tags and Peakkong Special Steel product tags to achieve comprehensive traceability and identification. According to the corresponding steel standards, corresponding material certificates will be provided.

Unit B, 9/F, Worldwide Centre, 123 Tung Chau Street, Tai Kok Tsui Kowloon.HongKong.

T: +852-29811161

E: sales@peakkong.com

No. 1 Building 1, No. 6 Xiegang Jinhai Road, Xiegang Town, Dongguan City, Guangdong Province.

T: 0769-82869307

E: admin@peakkong.com

- Previous:High performance alloy stainless steel profiles

- Next:Already the latest article

+

+