Titanium Grade 7 (Ti Gr 7 / 3.7235 / UNS R52400) is highly valued in various industries for its excellent corrosion resistance and mechanical properties. The following is a detailed overview of its application in structural hollow profiles (or stations):

Chemical Processing Equipment

Hollow pipe and tubing: Used to construct hollow pipes that carry corrosive chemicals, acids, and other hazardous materials to ensure durability and leak-proofing.

Heat exchangers: Hollow profiles used in the manufacture of heat exchangers, where resistance to corrosion and high temperatures is crucial.

Marine Structures

Support structures: Support beams and frames used in marine environments where exposure to seawater requires high corrosion resistance.

Subsea Applications: Suitable for subsea structures, including risers and manifolds, providing strength and reliability in harsh conditions.

Aerospace Parts

Lightweight structures: Applied to aerospace parts where weight reduction is critical, such as wing structures and fuselage frames.

Hollow profiles for increased strength: Used for hollow profiles that require a high strength-to-weight ratio to improve the overall performance of the aircraft.

Nuclear power facilities

Structural Support: Used to build support structures within nuclear reactors to ensure safety and stability in critical environments.

Containment Systems: For the design of containment systems that require rugged radiation-resistant and corrosion-resistant materials.

1. Corrosion Resistance: Excellent resistance to aggressive environments, making it ideal for chemical processing and marine applications.

2. High strength-to-weight ratio: Reduce the weight of the structure while maintaining strength, which is beneficial for aerospace and structural applications.

3. Ductility and formability: allows complex shapes and designs to adapt to various engineering requirements.

4. Temperature resistance: Maintains mechanical properties at high temperatures, suitable for high temperature applications.

5. Reduced Maintenance Requirements: Titanium’s durability minimizes maintenance requirements, thereby reducing operating costs.

Cost: The higher cost of titanium compared to traditional materials can be a barrier, although the long-term benefits often outweigh the initial expense.

Manufacturing Challenges: Requires specialized cutting and welding techniques, skilled labor and appropriate equipment.

If you have any other questions or need more specific details, please feel free to ask Peak Kong Special Steel!

-

2024-7-16 Laser welding of advanced high-strength steels (AHSS)

2024-7-16 Laser welding of advanced high-strength steels (AHSS) -

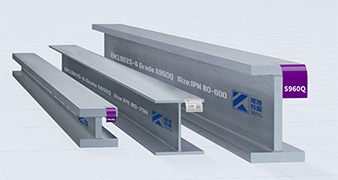

2024-7-19 Innovative Application of S960Q/S960QL/S960QL1 Structure steel

2024-7-19 Innovative Application of S960Q/S960QL/S960QL1 Structure steel -

2024-9-25 1.4301 Stainless steel hollow structural profiles

2024-9-25 1.4301 Stainless steel hollow structural profiles -

2024-9-20 Application of Ti Gr 2 / 3.7035 structural profiles in marine industry

2024-9-20 Application of Ti Gr 2 / 3.7035 structural profiles in marine industry -

2024-1-02 Laser welded stainless steel structural Section

2024-1-02 Laser welded stainless steel structural Section -

2024-9-27 What are the typical applications of 318LN stainless steel structural beams and columns?

2024-9-27 What are the typical applications of 318LN stainless steel structural beams and columns? -

2024-9-25 1.4301 Stainless Steel Structural Profile Performance

2024-9-25 1.4301 Stainless Steel Structural Profile Performance