Titanium Grade 2 (Ti Gr 2 / 3.7035) structural hollow sections are increasingly used in a variety of applications due to their excellent mechanical properties and corrosion resistance. The following is an overview of their applications, especially in structural hollow stations:

Marine Structures

– Support Frame: A support frame used in the construction of offshore platforms to provide strength while minimizing weight.

– Hull and superstructure: Hull and superstructure used in the shipbuilding industry due to its resistance to seawater corrosion.

Aerospace Industry

– Aircraft structures: for lightweight structural components such as fuselage frames and wing structures where weight reduction is critical.

– Spacecraft Parts: Ideal for structural elements in spacecraft that require high strength and low weight to withstand harsh conditions.

Chemical Processing

– Piping systems: Hollow profile pipes often used to convey corrosive materials, ensuring durability and reliability.

– Storage tanks: Storage tanks used to contain corrosive chemicals and have excellent corrosion resistance.

Architectural Applications

– Structural Framing: Columns and beams used in modern building designs to provide both aesthetic appeal and structural integrity.

– Facades and cladding: applied to building exteriors to provide a unique appearance while ensuring protection from environmental factors.

Nuclear Power Plant

– Structural supports: used in containment structures and support frames to ensure safety and stability in critical environments.

– Heat exchanger: used in cooling systems due to its corrosion resistance and ability to handle high temperatures.

1. Corrosion resistance: Excellent resistance to oxidation and corrosion, making it very suitable for use in corrosive environments.

2. High strength-to-weight ratio: Significant weight reduction compared to traditional materials, thereby improving performance in a variety of applications.

3. Ductility and formability: Good ductility allows a variety of manufacturing techniques, including bending and welding, which is critical for hollow structures.

4. Temperature resistance: Maintains mechanical properties at high temperatures, suitable for high temperature applications.

5. Biocompatibility: Ideal for medical applications requiring compatibility with human tissue.

– Cost: Titanium has higher material costs compared to traditional materials such as steel, which may limit its use in certain applications.

– Manufacturing challenges: Due to its unique properties, specialized cutting, welding and forming techniques and equipment are required.

If you need more specific information or examples, please feel free to ask Peak Kong Special Steel!

-

2024-9-25 Introduction to 254SMO and UNS S31254 Super Stainless Steel

2024-9-25 Introduction to 254SMO and UNS S31254 Super Stainless Steel -

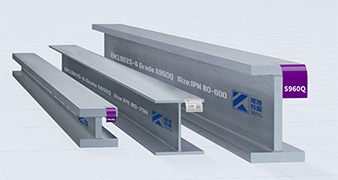

2024-7-19 Innovative Application of S960Q/S960QL/S960QL1 Structure steel

2024-7-19 Innovative Application of S960Q/S960QL/S960QL1 Structure steel -

2024-9-16 What are the common applications of 2205 duplex stainless steel?

2024-9-16 What are the common applications of 2205 duplex stainless steel? -

2024-9-24 S690 Universal Columns Innovative applications in structural works

2024-9-24 S690 Universal Columns Innovative applications in structural works -

2024-9-20 1.4404 stainless steel in innovative applications in bridges

2024-9-20 1.4404 stainless steel in innovative applications in bridges -

2024-9-16 316L Stainless Steel Performance Introduction:

2024-9-16 316L Stainless Steel Performance Introduction: -

2024-9-25 Super Duplex Stainless Steel UNS S32760 / 1.4501

2024-9-25 Super Duplex Stainless Steel UNS S32760 / 1.4501