Titanium Grade 1 (Ti Gr 1 / 3.7025) is widely used in structural beams and columns due to its unique properties. Here is an overview of its applications and benefits:

Aerospace Industry

– Aircraft structures: used in primary and secondary structures such as wing frames and fuselage components due to its high strength-to-weight ratio and corrosion resistance.

– Spacecraft components: Ideal for components exposed to extreme environments, including satellite structures and supports.

Marine Applications

– Shipbuilding: Due to its excellent corrosion resistance, used in ship hull structures and components to withstand seawater.

– Offshore platforms: critical for structural elements in harsh marine environments, including oil rigs and wind turbines.

Chemical Processing

– Pipes and Vessels: Used in the construction of pressure vessels and piping systems for transporting corrosive materials.

– Storage tanks: Suitable for storage of corrosive chemicals, with long service life and reliability.

Architectural Applications

– Structural frames: Used in modern building designs such as bridges and long-span roofs for their aesthetic appeal and structural capabilities.

– Facades and cladding: Provides corrosion resistance and a unique appearance to the building’s exterior.

1. Corrosion resistance: Excellent anti-oxidation and corrosion resistance, making it suitable for harsh environments.

2. High strength-to-weight ratio: Significant weight savings compared to steel, improving performance in weight-critical applications.

3. Ductility and formability: Good ductility allows for a variety of manufacturing techniques, including bending and welding.

4. Temperature resistance: Maintains mechanical properties at high temperatures, suitable for high temperature applications.

5. Biocompatibility: Ideal for medical applications requiring compatibility with human tissue.

– Cost: Titanium is more expensive than traditional materials such as steel, which can be a limiting factor in some applications.

– Manufacturing challenges: Due to its unique properties, specialized cutting, welding and forming techniques and equipment are required.

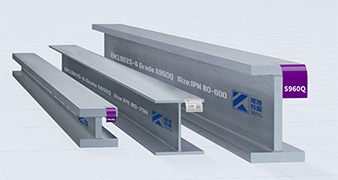

Peak Kong Special Steel Co., Limited. provides structural profiles such as I-beams, H-beams, channel steels, angle steels, square tubes, flat tubes, and round tubes.

If you need more specific information or examples, please feel free to ask Peak Kong Special Steel!

-

2024-9-16 Introduction to the performance of 2205 duplex stainless steel

2024-9-16 Introduction to the performance of 2205 duplex stainless steel -

2024-9-27 In what types of applications or environments are 926 (1.4529) stainless steel beams and columns typically used?

2024-9-27 In what types of applications or environments are 926 (1.4529) stainless steel beams and columns typically used? -

2024-2-20 Stainless steel 904L (1.4539)

2024-2-20 Stainless steel 904L (1.4539) -

2024-4-03 Advantages and applications of stainless steel hollow profiles

2024-4-03 Advantages and applications of stainless steel hollow profiles -

2024-7-19 Innovative Application of S960Q/S960QL/S960QL1 Structure steel

2024-7-19 Innovative Application of S960Q/S960QL/S960QL1 Structure steel -

2024-9-16 Innovative applications of duplex and super duplex stainless steel structural sections:

2024-9-16 Innovative applications of duplex and super duplex stainless steel structural sections: -

2024-9-16 2205 duplex stainless steel in bridges of Innovative application

2024-9-16 2205 duplex stainless steel in bridges of Innovative application